Evaluation of Respirator Change Schedules

- Determine the change schedule per manufacturer’s recommendations

or by using one of the methods listed on OSHA’s Web page located at http://www.osha-slc.gov/SLTC/respiratory_advisor/mainpage.html.

- Immediately before changing the cartridges being used based on the procedures determined in step 1, test for breakthrough using any sampling method with sufficient sensitivity to detect the chemical of interest below the Occupational Exposure Limit (OEL). These procedures should be performed immediately after leaving the work area, and should not be performed during the next work day. Methods that you may use include detector tubes, direct reading instruments such as a photoionization detectors, and charcoal tubes which require laboratory analysis.

The OEL is normally the health based workplace permissible exposure limit (PEL) or short term exposure limit (STEL) required by OSHA standards. In cases where there is no OSHA workplace exposure limit, use other exposure limits published by the American Conference of Governmental Industrial Hygienists (ACGIH), the American Industrial Hygiene Association, or the National Institute of Occupational Safety and Health.

You can test by using one of the following procedures provide your evaluate the respiratory hazard(s) to which the employee is exposed, and use the procedure frequently enough to ensure that workers are being protected by their respirators under the actual workplace conditions.

Procedure 1: Using a leak free cartridge holder, adaptors, inert tubing and tee such as teflon or stainless steel, sampling tube, and a sampling pump as shown in Figure 1, draw air through the cartridge being replaced. Perform sampling in a high exposure area so that an adequate detection limit can be obtained. You can perform sampling by attaching the sampling tube to the tee using a short piece of tubing to minimize the "dead space" in the tubing. If possible, insert the sampling tube directly into the contaminant air stream in the tee. If breakthrough occurs, the cartridge is no longer performing as designed and the change schedule should be shortened. Therefore, shorten the change schedule by one hour and repeat the test.

Figure 1.

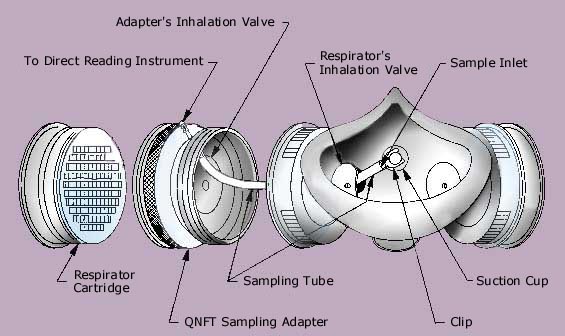

Procedure 2: Place a quantitative fit-testing (QNFT) sampling adapter between the cartridge and the face piece (Fig. 2). These adapters are often available through your respirator supplier.

Figure 2.

You can connect the direct reading instrument using a short piece of tubing made of teflon or other inert material to the outer hose connection on the adapter which, in turn, connects to a small inert sample tube on the inside of the adaptor. Keep the length of tubing as short as possible to minimize the "dead space" in the tubing. The sample tube passes through the respirator’s inhalation valve and is firmly positioned via a small suction cup and clip so that a sample can be drawn directly from the breathing zone of the respirator (i.e., between the cartridge and the respirator).

If breakthrough occurs, the cartridge is no longer performing as designed and the change schedule should be shortened. Therefore, shorten the change schedule by one hour and repeat the test.

A reading on the instrument may not be due to breakthrough, but may be due to other reasons such as a poor respirator fit, or exhalation of chemicals that have been absorbed into through the skin. Check the respirator fit using a positive and negative pressure test to verify that leakage is not occurring and verify that any personnel protective equipment, such as gloves, is being effectively used and that no skin absorption is occurring.

Since use of the QNFT adapter temporarily voids the respirator’s NIOSH approval, it may be put in place only temporarily during a short equilibration period before sampling to evaluate the change schedule.

- Reevaluate change schedules if employee exposure may increase

due to: (1) change in operations such as using more raw materials or

higher concentrations, (2) working without local exhaust ventilation

or other ventilation changes occur, (3) employee tasks or durations of

tasks change, or (4) employees experience symptoms of breakthrough

such as odor,

taste, or irritation. For compounds without adequate warning

properties, re-evaluate the change schedule any time an odor

is detected.

- Normally you should sample the toxic agent of interest. Sometimes, adequate direct reading sampling procedures are not available for the contaminant. In this case, a sampling method requiring a laboratory analysis may be required. Or, in some cases, a surrogate may be used. For example, a solvent carrier may be monitored if a direct reading instrument is not available for the contaminant of interest. You should use this variation only when calculations or manufacturer’s recommendations indicate that the toxic compound of interest has a longer breakthrough time than the solvent, and therefore the solvent will break through first.