1. General Discussion

1.1 Background

1.1.1 History of procedure

The OSHA Laboratory recently received samples collected

on silica gel requesting analysis for p-chloroaniline. Several

analytical procedures were tried, including gas chromatography and

liquid chromatography, but the sensitivity of the liquid

chromatography method was greater, and therefore it was used. The

liquid chromatograph had an ultraviolet detector set at 254 nm, a

secondary wavelength of 280 nm can also be used. The samples were

desorbed with methanol and the desorption efficiency was 100%.

1.1.2 Potential workplace exposure

Workers are

exposed to p-chloroaniline in many industries, with the majority of

them in the chemical manufacturing industries. It is used in azoic

coupling compounds and dye manufacturing (Ref. 5.1).

1.1.3 Toxic Effects (This section is included for information

only and should not be taken as a basis of OSHA policy.)

Exposure to p-chloroaniline is irritating to skin, eyes,

mucous membranes, and through oral ingestion and inhalation. Upon

entering the bloodstream p-chloroaniline damages the blood cells. The

lowest toxic concentration by inhalation in humans was 44

mg/m3(8.4 ppm). The lowest lethal dose through oral

ingestion in rats was 300 mg/kg. The lowest lethal dose applied

dermally in rabbits was 36 mg/kg (Ref. 5.2).

1.1.4

Physical properties: (Ref. 5.3)

| Molecular weight:

127.57 |

| Melting point:

72.5°C |

| Boiling point:

232°C |

| Odor:

aniline-like |

| Color: white to pale

gray |

| Vapor pressure: 1 mm

at 59.3°C |

| Molecular formula:

ClC6H4NH2 |

| Structure: |

1.2 Limit defining parameters

1.2.1 The detection limit of the

analytical procedure is 6 ng/injection. This is the smallest amount

that could be easily detected under normal analytical conditions.

The injection size was 10 µL.

1.2.2 The detection

limit of the overall procedure is 6 ng/sample (0.02 ppm based on a

6-liter sample). This is the amount of analyte placed on a silica gel

tube which corresponds to the detection limit of the analytical

procedure.

1.3

Advantages

1.3.1 The sampling procedure is

convenient.

1.3.2 The analytical method is reproducible

and

sensitive.

1.3.3 Re-analysis of samples is

possible.

1.3.4 It may be possible to analyze other

compounds

at the same time.

1.3.5 Interferences

may be avoided by proper selection of column and

parameters.

1.4

Disadvantages

1.4.1 Silica gel tubes adsorb

water vapor from, the air, thereby possibly lowering the capacity of

the tube for p-chloroaniline.

2. Sampling

procedure

2.1 Apparatus

2.1.1 A calibrated personal

sampling pump, the flow

of which can be determined within +

5% at the recommended flow.

2.1.2 Silica gel tubes

(20/40 mesh) containing 150-mg adsorbing section with a 75-mg backup

section separated by a 2 mm portion of urethane foam, with a

silane-treated glass wool plug before the adsorbing section and a 3-mm

plug of urethane foam at the back of the backup section. The ends are

flame sealed and the glass tube containing the adsorbent is 7-mm long,

with a 6-mm O.D. and 4-mm I.D., SKC tubes or equivalent.

2.2 Sampling technique

2.2.1 The ends of the silica gel

tube are opened immediately before sampling.

2.2.2

Connect the silica gel tube to the sampling pump with flexible tubing.

2.2.3 Tubes should be placed in a vertical position to

minimize channeling, with the smaller section towards the pump.

2.2.4 Air being sampled should not pass through any hose or

tubing before entering the silica gel tube.

2.2.5 Seal

the silica gel tube with plastic caps immediately after sampling. Seal

each sample lengthwise with OSHA Form-21 sealing tape.

2.2.6 With each batch of samples, submit at least

one

blank tube from the same lot used for samples. This tube

should be subjected to exactly the same handling as the samples (break

ends, seal, & transport) except that no air is drawn through

it.

2.2.7 Transport the samples (and corresponding

paperwork) to the lab for analysis.

2.2.8 Bulks

submitted for analysis must be shipped in a separate container from

the samples.

2.3

Desorption efficiency

2.3.1 The desorption efficiency

averaged 100% at the concentration of 149.2 µg loading on the tubes,

or 4.77 ppm based on a 6 liter air sample (see Table 2.3.2).

2.3.2 The desorption study was generated by spiking 298.3,

149.2, or 74.59 µg of p-chloroaniline onto six tubes at each level and

storing overnight at room temperature. They were opened the next day,

desorbed with 1-mL methanol, and analyzed by LC-UV.

Table 2.3.2

| Level spiked (µg) |

%Recovered |

| 298.3 |

98.7 |

| 298.3 |

102 |

| 298.3 |

102 |

| 298.3 |

102 |

| 298.3 |

99.7 |

| 298.3 |

99.8 |

| average |

101 |

| |

|

| 149.2 |

101 |

| 149.2 |

101 |

| 149.2 |

99.8 |

| 149.2 |

102 |

| 149.2 |

101 |

| 149.2 |

102 |

| average |

101 |

| |

|

| 74.59 |

99.1 |

| 74.59 |

98.4 |

| 74.59 |

101 |

| 74.59 |

101 |

| 74.59 |

102 |

| 74.59 |

104 |

| average |

101 |

| overall average |

101 |

| standard deviation |

±1.44 |

2.4 Retention efficiency

2.4.1 The retention efficiency was

performed by liquid spiking silica gel tubes with 149.2 µg

p-chloroaniline and drawing a known volume of humid air (R.H. 86%)

through the tubes. There was little loss of the p--chloroaniline (see

Table 2.4.2).

2.4.2 Twelve samples were spiked with 149.2 µg

p-chloroaniline. Six had 3 liters, and the other six samples had 6

liters of humid air drawn through them. There was 1.6% loss with 3

liters and 2.9% loss with 6 liters humid air

drawn.

Table 2.4.2

| Tube # |

Liters drawn |

% recovered |

| 1 |

3 |

98.0 |

| 2 |

3 |

98.8 |

| 3 |

3 |

99.7 |

| 4 |

3 |

99.3 |

| 5 |

3 |

96.4 |

| 6 |

3 |

96.4 |

| average |

3 |

98.4 |

| |

|

|

| 7 |

6 |

98.2 |

| 8 |

6 |

96.0 |

| 9 |

6 |

98.2 |

| 10 |

6 |

98.1 |

| 11 |

6 |

95.0 |

| 12 |

6 |

lost in

analysis |

| average |

6 |

97.1 |

2.5. Storage

2.5.1 Storage study was performed over

a 14-day period with little loss of p-chloroaniline (see Table

2.5.2).

2.5.2 The tubes were spiked with 149.2 µg/tube.

They were analyzed on days 1, 6, 11, and 14. The day I samples were

used for the desorption study.

Table 2.5.2

| Day |

% Recovered |

| 1 |

101 |

| 1 |

101 |

| 1 |

99.8 |

| 1 |

102 |

| 1 |

101 |

| 1 |

102 |

| 6 |

96.5 |

| 6 |

97.3 |

| 6 |

95.6 |

| 11 |

99.6 |

| 11 |

97.9 |

| 11 |

99.8 |

| 14 |

97.5 |

| 14 |

97.3 |

| 14 |

100 |

2.6.Air volume and sampling rate studied

2.6.1 The air volume studied is 6

liters.

2.6.2 The sampling rate studied is 0.1 liters

per minute.

2.7

Interferences

2.7.1 Water vapor may cause a

decrease in the collection capacity of p-chloroaniline.

2.7.2 Suspected interferences should be listed on sample data

sheets.

2.8 Safety

precautions

2.8.1 Sampling equipment should be

placed on an employee in a manner that does not interfere with work

performance or safety.

2.8.2 Safety glasses should be

worn at all times.

2.8.3 Follow all safety practices

that apply to the workplace being sampled.

3. Analytical method

3.1 Apparatus

3.1.1 Liquid chromatograph

equipped with an ultraviolet detector at 254 rim.

3.1.2 LC column capable of separating the analyte from any

interferences. An Alltech C18 column was used in this evaluation.

3.1.3 An electronic integrator or some other suitable method

of measuring peak areas.

3.1.4 Two milliliter vials with

Teflon-lined caps.

3.1.5 A 10-µL syringe or other

convenient size for sample injection.

3.1.6 Pipets for

dispensing the desorbing solvent. The Glenco 1-mL dispenser was used

in this method.

3.1.7 Volumetric flasks 10 mL and other

convenient sizes for preparing standards.

3.2 Reagents

3.2.1 Methanol HPLC grade.

3.2.2 Millipore deionized, water.

3.3 Sample preparation

3.3.1 Sample tubes are opened and

the front and back section of each tube are placed in separate

2-mL vials.

3.3.2 Each section is desorbed with 1 mL

methanol.

3.3.3 The vials are sealed immediately and allowed

to desorb for 30 minutes with occasional shaking.

3.4 Standard

preparation

3.4.1 Standards are prepared by

diluting a known quantity of p-chloroaniline with methanol..

3.4.2 At least two separate stock standards should be made.

Dilutions of these stock standards are made. The range used in this

method was from 1492 ug/mL to 0.6 ug/mL.

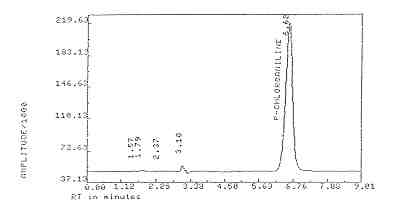

3.5 Analysis

3.5.1 Liquid chromatograph

conditions

| Solvent

mixture: |

65% methanol 35%

water |

| Injection size: |

10 µL |

| Elution time: |

6.62 minutes |

| Wavelength: |

254 nm |

| Flow rate: |

1mL/min |

| Column: |

Alltech

C18 |

| Chromatogram: |

(See Figure

1) |

3.5.2. Peak areas are measured

by an integrator or other suitable means.

3.6. Interferences (analytical)

3.6.1. Any compound having the

general retention time of the analyte is an interference.

Possible interferences should be listed on the sample data sheet. LC

parameters should be adjusted if necessary so these interferences will

pose no problems.

3.6.2. Retention time data on a single

column is not considered proof of chemical identity. Samples over the

target concentration should be confirmed by GC/Mass Spec or other

suitable means.

3.7.

Calculations

3.7.1 To calculate the ppm of

analyte in standards based on a 6 liter air sample, and a 1-mL

desorbing solution:

| 24.46 |

= Molar volume

(liters/mole) at 25°C and 760 mmHg. |

| MW |

= Molecular

weight |

| p |

= Density |

| 1 mL |

= Desorption rate |

| 6 L |

= 6 liter air

sample |

| DE |

= Desorption

efficiency |

3.7.2 This calculation

is done for each section of the sampling tube and the results added

together.

3.8.Safety

precautions

3.8.1 All handling of solvents

should be done in a hood.

3.8.2 Avoid skin contact with

all solvents.

3.8.3 Wear safety glasses at all

times.

4.

Recommendations for further study vapor generated samples in both dry and

humid air should be performed to check adsorption of p-chloroaniline on

silica gel tubes. Since there may be a problem with water vapor replacing

the p-chloroaniline on the silica gel tubes, the retention efficiency at

larger air volumes of humid air needs to be

studied.

5.

References

5.1 Mark, H.F., Othmer, D.F.,

Overberger, C.G., Seaborg, G.T., "Encyclopedia of Chemical Technology",

Third Edition, John Wiley & Son, N.Y., 1978, Vol. 2, p. 318.

5.2 Sax, N.I., "Dangerous Properties of Industrial materials",

Fifth Edition, Van Nostrand Reinhold Co., N.Y., 1979, p.488.

5.3 Windholz, M., "The Merck Index", Tenth Edition, Merck &

Co., Rahway N.J., 1983, p.297.

|