|

| Method no.: |

W4001 |

| |

|

| Control no.: |

T-W4001-FV-02-0104-M |

| |

|

| Target concentration: |

0.050 µg/100 cm2 |

| |

|

| Procedure: |

Wipe samples are collected by

using firm hand pressure to move a 37-mm diameter polyvinyl

chloride (PVC) filter, 5-µm pore

size, across the surface of interest. An alternate medium for

rough surfaces is a 37-mm binderless quartz fiber filter.

Samples are digested with multiple buffered solutions. After

dilution, an aliquot of this solution is analyzed for

hexavalent chromium (Cr(VI)) by ion chromatography with

postcolumn derivatization of the Cr(VI) with 1,5-diphenyl

carbazide and detected by a UV-vis detector at 540 nm. |

| |

|

| Special

requirements: |

In chrome plating environments,

wipe samples taken on a PVC filter or an uncoated binderless

quartz fiber filter, should be placed in a vial containing 5

mL of an aqueous solution containing 10%

Na2CO3 with 2% NaHCO3

immediately after sampling to eliminate the interference from

the acid used in the chrome plating process. An alternate

medium which does not require extraction in the field is a

binderless quartz fiber filter coated with 1% NaOH. |

| |

|

| Reliable quantitation limit: |

3 ng/sample |

| |

|

| Status of method: |

Evaluated method. This method

has been subjected to the established evaluation procedures of

the Methods Development Team. |

| |

|

| April 2001 |

Mary E. Eide |

| |

|

Methods Development Team

Industrial Hygiene

Chemistry Division

OSHA Salt Lake Technical Center

Sandy

UT 84070-6407

|

1. General Discussion

1.1 Background

1.1.1 History

This wipe sampling

method was developed to provide a means of taking wipe

samples for hexavalent chromium (Cr(VI)). The OSHA SLTC

has received wipe samples taken on a variety of media,

including PVC filters, baby wipes, paper filters such as

Whatman filter, glass fiber filter, and mixed cellulose

ester filter. The Cr(VI) decomposed to trivalent chromium

(Cr(III)) on all of these media except the PVC filters.

The Evaluation Guidelines for Surface Sampling

Methods(1)

specifies the use of fabric wipes, whenever possible. The

cloth-like wipes which were tried, Durx 670

(polyester/cotton nonwoven fabric) and pro-Wipe 880

(polyester woven fabric), did not work because the Cr(VI)

reacted with them, changing it to Cr(III), so they could

not be used for this evaluation. Wipe samples were first

evaluated by collection on PVC filters, and analyzed

following the analytical procedure in OSHA Method

ID-215.(2)

Because PVC filters may tear on rough surfaces, a

binderless quartz fiber filter was also evaluated and

found to have good recoveries. In chrome plating

processes, there is an additional interference of the

acid, which changes the Cr(VI) to Cr(III), upon storage.

Both the samples collected on the PVC filters and the

binderless quartz fiber filters had a significant loss in

a 15 day storage. This loss was eliminated by placing the

samples taken on either the PVC filters or the binderless

quartz fiber filters in a vial containing 5-mL of an

aqueous solution containing 10% sodium carbonate

(Na2CO3)/2% sodium bicarbonate

(NaHCO3) immediately after sampling. An

alternate medium, which requires no field extraction,

binderless quartz fiber filters coated with 1% NaOH, was

also evaluated for sampling in the chrome plating

environment, and found to give good recoveries.

A

glass plate was first chosen for an ideal surface to check

the surface sampler removal efficiency, but Cr(VI)

interacted with the glass plate changing to Cr(III). The

PTFE surface was chosen as an ideal surface for this

method because of its inertness, and it gave good

recoveries for wipe sampling.

Following the

procedure in OSHA Method ID-215(3),

the filters, of all types, had extraction and digestion

with multiple buffers, separation by ion chromatography,

with post-column derivatization and detection by UV-vis at

540 nm. In this evaluation, the filter is digested in an

aqueous solution containing 10% sodium carbonate

(Na2CO3)/2% sodium bicarbonate

(NaHCO3) and the mixture of phosphate

buffer/magnesium sulfate. After dilution with DI water, an

aliquot of this solution is analyzed for Cr(VI) using an

ion chromatograph equipped with a UV-vis detector at 540

nm. A post-column derivatization of the Cr(VI) with

1,5-diphenyl carbazide is performed prior to detection.

The phosphate buffer and magnesium sulfate solutions are

added to precipitate other metals, especially Fe(II), so

that they do not reduce Cr(VI) changing it to Cr(III).

This was shown in the interferences studies in OSHA Method

ID-215(4).

The Cr(III) is also precipitated to prevent it from

oxidizing to Cr(VI).

For analysis of samples taken

in spray paint operations, it is necessary to perform a

second extraction of the filter with an aqueous solution

of 5% NaOH/ 7.5% Na2CO3, with the

addition of the phosphate buffer/magnesium sulfate, to

remove the Cr(VI) from the hardened paint matrix. Again,

the phosphate buffer with the magnesium sulfate is added

to the NaOH/Na2CO3 to precipitate

the other metals, and prevent them from interacting with

the Cr(VI).

Samples taken in a chrome plating

operation have the additional interference of the acid or

acids, which convert the Cr(VI) to Cr(III), as the samples

are stored. The chrome plating bath usually contains

sulfuric acid, so a mixture of sulfuric acid and Cr(VI) in

water was prepared to emulate the chrome plating solution.

The recovery on Day 15 of storage at ambient temperature

was 78.0% for PVC filters spiked with this mixture of

Cr(VI) and H2SO4, and 81.0% for

refrigerated samples. Samples taken of this mixture of

Cr(VI) and H2SO4 on PVC filters,

immediately placed into a vial containing a solution of

10% Na2CO3 with 2% NaHCO3

after sampling, to neutralize the acid, and stored at

ambient temperature had a 97.4% recovery on Day 15.

Binderless quartz fiber filters had a loss of Cr(VI)when

stored, with an ambient recovery of 86.1% on Day 15. When

the binderless quartz fiber filters were placed

immediately into a vial containing a solution of 10%

Na2CO3 with 2% NaHCO3

after sampling, the ambient recovery was 97.9% on Day 15.

The method for collecting Cr(VI) air samples in chrome

plating operations used in the UK is with a binderless

quartz fiber filter coated with 1% NaOH.(5)

The NaOH coating neutralizes the acid or acids, halting

their reaction with the Cr(VI). The recovery of Cr(VI)

from wipe samples spiked with the mixture of Cr(VI) and

H2SO4 using the 1% NaOH coated

binderless quartz fiber filters had a recovery of 96.4%

for ambient samples on Day 15. The 1% NaOH coated

binderless quartz fiber filters are digested and analyzed

in the same fashion as the PVC filters. These storage

results indicate that for samples taken in chrome plating

operations, the uncoated filters should be placed into a

vial containing a solution of 10%

Na2CO3 with 2% NaHCO3

after sampling, or a 1% NaOH coated binderless quartz

fiber filter should be used.

1.1.2 Toxic effects

(This section is for information only and should not be

taken as the basis of OSHA policy.)

Some of the

water soluble salts of chromic acid, (potassium

dichromate, potassium chromate, sodium dichromate, and

sodium chromate) are very corrosive and can cause burns

which can facilitate the adsorption of these compounds

through the skin.(6)

Cr(VI) causes skin ulcers, blisters, burns, irritation to

mucous membranes, and eye irritation. Workers sensitized

to Cr(VI) compounds experience allergic dermatitis

reactions. Acute dermal exposure can result in necrosis of

the skin and underlying tissue and sloughing of the

skin.(7)

Kidney damage has been reported in workers where skin

absorption has occurred. There have been reports of lung

cancer in workers exposed to chrome pigments in Germany,

Norway, and the United States.(8)

ACGIH has a TLV of 0.05 mg/m3 for water soluble

Cr(VI) compounds and 0.01 mg/m3 for insoluble

Cr(VI) compounds and classify them as recognized human

carcinogens.(9)

ACGIH recommends BEI (Biological Exposure Indices)

not exceed 10 µg/g creatinine

for the increase in urinary chromium concentrations during

the workshift, obtained by comparing a urine sample from

before the shift to one at the end of the shift, and 30

µg/g creatinine for the end of

the workweek at the end of the shift. The chromium

measured in urine is Cr(III), as Cr(VI) is enzymatically

reduced to Cr(III). The preshift urine sample is necessary

because Cr(III) is a nutrient necessary for humans, and it

is often included in vitamin preparations, or is taken as

a supplement. Other common sources of chromium are smoking

and water supplies. The BEI is based on the difference

between the two urine samples.(10)

1.1.3 Workplace exposure(11)

Cr(VI) is primarily used in the form of chromium

trioxide, and the chromates and dichromates of sodium,

potassium, ammonium, calcium, barium, zinc, strontium, and

lead. These compounds are used in photography, dyeing,

electroplating, paints, as rust inhibitors, as pigments,

and as oxidizing agents in tanning.

1.1.4 Physical

properties (12)

( the physical properties listed below are for chromium

trioxide, for physical properties of the other common

salts containing Cr(VI) see OSHA Method ID-215 (13))

| synonyms: |

chromic acid,

chromic anhydride, chromia, chromic trioxide |

| CAS number: |

1333-82-0 |

| molecular weight: |

100.01 |

| IMIS number: |

0686(14) |

| melting point: |

196ºC |

| structural

formula: |

CrO3

|

| solubility: |

very sol in water,

insol in alcohol |

| appearance: |

dark purple-red

crystals |

fire and

explosion hazard:

|

a very

powerful oxidizing agent, which can cause violent

reactions when in contact with organic matter or

reducing

agents |

This method was evaluated according to the

OSHA SLTC "Evaluation Guidelines for Surface Sampling

Methods".(15)

The Guidelines define analytical parameters, specify required

laboratory tests, statistical calculations and acceptance

criteria. The analyte surface concentrations throughout this

method are based on the recommended sampling and analytical

parameters.

1.2 Limit defining parameters

1.2.1 Detection limit of the analytical

procedure

The DLAP was calculated to be 0.09 ng.

This is the lowest amount of analyte that will give a

detector response that is significantly different from the

response of a reagent blank. (Section 4.1)

1.2.2

Detection limit of the overall procedure

The

detection limit of the overall procedure for PVC filters

is 0.91 ng per sample, binderless quartz fiber filters is

0.67 ng per sample, and 1% NaOH coated binderless quartz

fiber filters is 0.94 ng per sample. This is the lowest

amount of Cr(VI) spiked on the wipe sampler that will give

a detector response that is significantly different from

the response of wipe sampler blanks. (Section 4.2 )

1.2.3 Reliable quantitation limit

The

reliable quantitation limit for PVC filters is 3.04 ng per

sample, binderless quartz fiber filters is 2.23 ng per

sample, and 1% NaOH coated binderless quartz fiber filters

is 3.12 ng per sample. This is the lowest amount of Cr(VI)

spiked on the wipe sampler that will give a detector

response that is considered the lower limit for precise

quantitative measurements. (Section 4.2)

1.2.4

Recovery

The recovery of Cr(VI) from samples

spiked on PVC filters used in a 15-day storage test

remained above 96.4% when the samples were stored at 22ºC.

(Section 4.3)

The recovery of Cr(VI) from samples

spiked on binderless quartz fiber filters used in a 15-day

storage test remained above 96.4 % when the samples were

stored at 22ºC. (Section 4.3)

The recovery of

Cr(VI) from samples spiked with a mixture of

H2SO4 and Cr(VI)(to simulate a

chrome plating operation) on PVC filters, then immediately

placed into a vial containing 5 mL of an aqueous solution

containing 10% Na2CO3 with 2%

NaHCO3, used in a 15-day storage test, remained

above 97.9% when the samples were stored at 22°C. (Section

4.3)

The recovery of Cr(VI) from samples spiked

with a mixture of H2SO4 and

Cr(VI)(to simulate a chrome plating operation) on

binderless quartz fiber filters, then immediately placed

into a vial containing 5 mL of an aqueous solution

containing 10% Na2CO3 with 2%

NaHCO3, used in a 15-day storage test, remained

above 97.9% when the samples were stored at 22ºC. (Section

4.3)

The recovery of Cr(VI) from samples spiked

with a mixture of H2SO4 and

Cr(VI)(to simulate a chrome plating operation) on 1% NaOH

coated binderless quartz fiber filters used in a 15-day

storage test remained above 96.4% when the samples were

stored at 22ºC. (Section 4.3)

1.2.5 Surface

sampler removal efficiency

The removal efficiency

of filters spiked with Cr(VI) at the target concentration

of 0.05 µg/100 cm2 is

96.8% for PVC, 97.7% for binderless quartz fiber filters,

and 97.0% for binderless quartz fiber filters coated with

1% NaOH . This is the percentage of Cr(VI) that was

removed from a sheet of PTFE that was spiked at the target

concentration. (Section 4.4)

1.2.6 Sampling

reproducibility and analytical reproducibility

Six

PTFE surfaces were spiked at the target concentration. A

chemist, other than the one developing the method,

conducted sampling on the PTFE surfaces, with the filters,

as described in Section 2. The test was repeated with a

second chemist performing the sampling. The samples were

analyzed. For the PVC filters the first chemist was able

to achieve a removal efficiency of 96.0%, and the second

chemist was able to achieve a removal efficiency of 95.1%.

(Section 4.6.1) For the binderless quartz fiber filters

the first chemist was able to achieve a removal efficiency

of 95.9%, and the second chemist was able to achieve a

removal efficiency of 96.0%. (Section 4.6.3) For the 1%

NaOH coated binderless quartz fiber filters the first

chemist was able to achieve a removal efficiency of 96.0%,

and the second chemist was able to achieve a removal

efficiency of 96.5%. (Section 4.6.5)

Six samples

spiked on each of the three kinds of filters at the target

concentration by liquid injection were submitted for

analysis by the OSHA Salt Lake Technical Center. The

samples on PVC filters were analyzed according to a draft

copy of this procedure after 13 days of storage at 23ºC,

with an average analytical result of 97.6% of theoretical

(Section 4.6.2). The binderless quartz fiber filters were

analyzed after 5 days of storage at 23ºC and had an

average analytical result was 96.5% of theoretical

(Section 4.6.4). The 1% NaOH coated binderless quartz

fiber filters were analyzed after 9 days of storage at

23ºC, with an average analytical result was 95.8% of

theoretical (Section 4.6.6).

2. Sampling

Procedure

All safety

practices that apply to the work area being sampled should be

followed. Sampling should be conducted in such a manner that

it will not interfere with work performance or safety. It is

important to wear gloves when handling the 1% NaOH coated

binderless quartz fiber filters as the NaOH coating is very

caustic.

2.1 Apparatus

Samples are collected with

37-mm diameter polyvinyl chloride (PVC) filters 5-µm pore size (MSA part # 625413).

On rough surfaces, samples are collected with 37-mm

diameter binderless quartz fiber filters 0.45-mm thick (SKC

part # 225-1809).

In chrome plating operations only,

samples can be collected with 37-mm diameter 1% NaOH coated

binderless quartz fiber filters 0.45-mm thick. (Section 4.9)

The selected gloves are to be resistant to

penetration of the chemical being sampled and any other

chemicals expected to be present. One pair of gloves per

sample taken should be used to avoid cross contamination of

samples.

Labeled vials, 20-mL glass scintillation

vials or other appropriate sized glass vial with PTFE lined

caps, one for each sample.

For samples taken in a

chrome plating operation, 5 mL of an aqueous solution

containing 10% Na2CO3 with 2%

NaHCO3 should be preloaded in the vials, if PVC

or uncoated binderless quartz fiber filters are used for

sampling.

2.2 Reagents

For samples taken in

a chrome plating operation, 5 mL of an aqueous solution

containing 10% Na2CO3 with 2%

NaHCO3 should be preloaded in the vials. (Section

3.2.15)

2.3 Technique

Prepare a sufficient

number of vials, each labeled with a unique number, for the

projected sampling needs.

Prepare a diagram of the

area or rooms to be wipe sampled along with the locations of

key surfaces.

Wear a new pair of clean gloves for

each sample to prevent contamination of future samples as

well as oneself. The selected gloves are to be resistant to

penetration of the chemical being sampled and any other

chemicals expected to be present. PVC gloves are suggested

for sampling Cr(VI) based on a review of a glove

manufacturer's chemical resistivity and degradation

information. Do not wear powdered gloves.

Record the

sample vial number and the location where the sample is

taken.

Remove the filter from the carrying container

with clean PTFE-coated tweezers or plastic tweezers. Do not

use metal tweezers to handle the filters as they will

deposit Cr(VI) onto filters.

Depending on the

purpose of the sample, it may be useful to determine the

surface loading of the contamination (e.g., in micrograms of

analyte per area). For these samples, it is necessary to

record the area of the surface wiped (e.g., 100

cm2). This would not be necessary for samples

taken to simply show the presence of the contaminant.

Surfaces should not be wetted with water as the

water will allow any metal interferences to interact with

the Cr(VI), thereby affecting the results.

Firm

pressure should be applied when wiping. Start at the outside

edge and progress toward the center making concentric

squares of decreasing size. Fold the filter with the

contaminant side inward and repeat.

Without allowing

the filter to come into contact with any other surface, fold

the filter with the exposed side inward. Place the filter in

a sample vial, cap and place a corresponding number at the

sample location on the diagram. Include notes with the

sketch giving any further description that may prove useful

when evaluating the sample results (e.g., a description of

the surface sampled, such as : pencil, doorknob, safety

glasses, lunch table, inside respirator, employee names,

etc.).

PVC and binderless quartz fiber filter

samples taken in a chrome plating operation should be placed

in a vial containing 5 mL of an aqueous solution containing

10% Na2CO3 with 2% NaHCO3

to stabilize the Cr(VI) to field extract them. An alternate

media only for chrome plating operations is a binderless

quartz fiber filter coated with 1% NaOH. The 1% NaOH coated

binderless quartz fiber filters do not require field

extraction. Gloves must be worn when handling these NaOH

coated filters as the NaOH is very caustic.

Submit

at least one blank wipe filter, treated in the same fashion,

but without wiping.

Record sample location,

employees names, surface area (if pertinent), work

description, type of operation, personal protective

equipment, and any other necessary information, along with

any potential interferences on the OSHA-91A form.

Submit the samples to the OSHA Salt Lake Technical

Center together with OSHA-91A forms as soon as possible

after sampling. Ship any bulk samples separate from the

surface samples.

2.4 Extraction efficiency

It is the responsibility of each analytical

laboratory to determine the extraction efficiency because

the wipe sampling media, reagents, and laboratory techniques

may be different than those listed in this evaluation and

could influence the results (Section 4.5).

The mean

extraction efficiency for Cr(VI) from PVC filters over the

range of 0.06 to 10 times the target concentration (3 to 500

nanograms per sample) was 96.6% for samples extracted with

the first extraction buffer (10%

Na2CO3 with 2% NaHCO3) and

96.9% for samples extracted with the second extraction

buffer (5% NaOH with 7.5% Na2CO3),

used for spray paint samples only.

The mean

extraction efficiency for Cr(VI) from binderless quartz

fiber filters over the range of 0.06 to 10 times the target

concentration (3 to 500 nanograms per sample) was 97.3% for

samples extracted with the first extraction buffer (10%

Na2CO3 with 2% NaHCO3) and

96.2% for samples extracted with the second extraction

buffer (5% NaOH with 7.5% Na2CO3),

used for spray paint samples only.

The mean

extraction efficiency for Cr(VI) from 1% NaOH coated

binderless quartz fiber filters over the range of 0.06 to 10

times the target concentration (3 to 500 nanograms per

sample) was 97.3% for samples extracted with the first

extraction buffer (10% Na2CO3 with 2%

NaHCO3) and 96.9% for samples extracted with the

second extraction buffer (5% NaOH with 7.5%

Na2CO3), used for spray paint samples

only.

2.5 Interferences, sampling

Suspected

interferences should be reported to the laboratory with

submitted samples. The interference studies were performed

in OSHA Method ID-215 Cr(VI)(16).

Cr(III) is the major positive interference and Fe(II) is the

major negative interference. In chrome plating operations,

the acid is also a negative interference.

3. Analytical

Procedure

Adhere to the

rules set down in your Chemical Hygiene Plan (17).

Avoid skin contact and inhalation of all chemicals and review

all appropriate MSDSs before beginning the analysis of

samples.

Analyze the samples using the analytical

procedure in OSHA Method ID-215 Hexavalent Chromium. (18)

3.1 Apparatus

3.1.1 Ion chromatograph with a UV-vis detector

and a postcolumn pump. A Dionex 4500i ion chromatograph

with a UV-vis detector, a pneumatic controlled postcolumn

reagent delivery system, and a reaction coil were used in

this evaluation.

3.1.2 IC column and guard column

which can separate Cr(VI) from any potential

interferences. A 250-mm × 4-mm i.d. Dionex IonPac AS7

column and 50-mm × 4-mm i.d. Dionex IonPac NG1 guard

column were used in this evaluation.

3.1.3 A means

to integrate the chromatograms. The Dionex AI450 software,

and a Millennium32 data system were used in

this evaluation.

3.1.4 Automatic sampler. A Dionex

model ASM-2, and sample vials, 0.5-mL, with filter caps

was used in this evaluation.

3.1.5 Volumetric

flasks, pipets, and calibrated micropipets.

3.1.6

Erlenmeyer flasks, 50-mL, for sample digestion.

3.1.7 Micro-analytical balance capable of weighing

at least 0.01 mg.

3.1.8 Polyethylene bottles, 1-L

size or larger, for extraction solutions.

3.1.9

Scintillation vials, glass, 20-mL.

3.1.10 Hotplate

temperature adjustable to 135ºC placed in an exhaust hood.

3.1.11 Equipment for eluent degassing. A vacuum

pump and ultrasonic bath were used for this evaluation.

3.1.12 Optional: Centrifuge for spinning down the

precipitate in samples. 3.2 Reagents

3.2.1 Deionized water 18 Mohm. A Millipore

Milli-Q system was used to prepare the water for this

evaluation.

3.2.2 Sodium carbonate

(NaCO3), reagent grade. Mallinckrodt 99+% lot

7527 KHKC was used in this evaluation.

3.2.3

Sodium bicarbonate (NaHCO3), reagent grade.

Baker Analyzed Reagent 99.9% pure lot D12721 was used in

this evaluation.

3.2.4 Potassium dichromate

(K2Cr2O7), reagent grade.

JT Baker Reagent grade 99% lot 715426 and Acros lot

A010583303 were used in this evaluation.

3.2.5

Magnesium sulfate (MgSO4), anhydrous, reagent

grade. ChemPure Reagent grade 99% lot M172KDHM was used in

this evaluation.

3.2.6 Ammonium sulfate

[(NH4)2SO4], reagent

grade. Aldrich 99+% lot OO427TQ was used in this

evaluation.

3.2.7 Ammonium hydroxide

(NH4OH) 29% solution. Baker analyzed Reagent

28.9% NH4OH lot 611248 was used in this

evaluation.

3.2.8 1,5-Diphenylcarbazide (DPC)

(C6H5NHNHCONHNHC6H5),

reagent grade. Aldrich 99+% lot 03017AR was used in this

evaluation.

3.2.9 Methyl alcohol

(CH3OH), HPLC grade. Fisher Optima 99.9% lot

966306 was used in this evaluation.

3.2.10

Sulfuric acid (H2SO4), concentrated.

JT Baker Instra-analyzed 96.8% lot E24049 was used in this

evaluation.

3.2.11 Nitric acid (HNO3),

concentrated (69-70%). JT Baker Instra-analyzed 69.0-70.0%

lot N46048 was used in this evaluation.

3.2.12

Potassium hydrogenphosphate trihydrate

(K2HPO4·3H2O), reagent

grade. Aldrich 99+% lot 01525MN was used in this

evaluation.

3.2.13 Potassium dihydrogenphosphate

(KH2PO4), reagent grade. Aldrich

99+% lot 06327KQ was used in this evaluation.

3.2.14 Nitric acid solution (10%): In a 1-L flask

place about 500-mL deionized water, add 100 mL

concentrated nitric acid, then fill up to the mark with

deionized water.

3.2.15 Buffer/extraction (BE)

solution ( 2% NaHCO3 with 10%

Na2CO3): In a 1-L flask place about

500-mL deionized water, add 20 g of NaHCO3,

swirl to dissolve, then add 100 g of

Na2CO3, and bring up to the mark

with deionized water. Shake to dissolve or use an

ultrasonic bath. Store in a polyethylene bottle.

3.2.16 Spray-paint extraction (SPE) solution (5%

NaOH with 7.5% Na2CO3): In a 1-L

flask place about 500-mL deionized water, add 50 g of

NaOH, swirl to dissolve, then add 75 g of

Na2CO3, and bring up to the mark

with deionized water. Prepare the solution monthly, and

store in a polyethylene bottle.

3.2.17 Magnesium

sulfate solution: In a 100-mL volumetric flask place about

50 mL deionized water, add 9.9 g of anhydrous magnesium

sulfate, mix well, and bring up to the mark with deionized

water.

3.2.18 Phosphate buffer solution (0.5 M

KH2PO4 with 0.5 M

K2HPO43H2O): In a 1-L

flask place about 500-mL deionized water, add 6.8 g of

KH2PO4 and 11.4 g of

K2HPO43H2O, swirl to

dissolve and bring up to the mark with deionized water.

3.2.19 Phosphate buffer/Mg(II) (PBM) solution: In

a 100-mL beaker place 50 mL of phosphate buffer, then add

25 mL of magnesium sulfate solution, and mix well. Prepare

fresh before each analysis, as this solution is only good

for 4 hours.

3.2.20 Dilute Buffer

Extraction/Phosphate buffer/Mg(II) solution (DBE/PBM

solution): In a 100-mL volumetric flask pipette 50 mL of

BE solution, add 15 mL of PBM solution, bring up to the

mark with deionized water, and mix. A precipitate of

magnesium hydroxide will form and slowly precipitate out

of solution. Allow the precipitation to settle for at

least 60 minutes, or place in a centrifuge at 3,200 rpm

for 5-10 min. Transfer the "clear" solution to a beaker

for use in preparation of working standards. Try to avoid

transfering any precipitate as it will clog the IC.

3.2.21 Eluent [250 mM

(NH4)2SO4 with 100 mM

NH4OH]: In a 1-L flask place about 500 mL of

deionized water, add 6.5 mL of the 29% ammonium hydroxide,

then add 33 g of ammonium sulfate and mix well. Dilute up

to the mark with deionized water. Degas the eluent before

use. In this evaluation, the eluent was degassed with

vacuum while in a ultrasonic bath. Transfer solution to

the eluent container on the IC.

3.2.22 Postcolumn

derivatization reagent (2.0 mM DPC in 90:10 1 N

H2SO4:methyl alcohol): In a 100-mL

volumetric flask place 0.5 g of DPC fill to the mark with

methyl alcohol and mix well. In a 1-L volumetric flask

place about 500 mL deionized water, add 28 mL concentrated

sulfuric acid, mix well, and allow to cool to room

temperature. When the sulfuric acid solution is at room

temperature, add the DPC/methanol solution, bring up to

the mark with deionized water, mix well, and allow to cool

to room temperature before placing in the postcolumn

reservoir. This solution must be at room temperature for

the complete reaction between DPC and Cr(VI). This

solution is stable for 3 days. For the most sensitivity,

this solution must be freshly prepared and be at room

temperature. 3.3 Standard preparation

3.3.1 Wash all glassware in hot water with

detergent, rinse with tap water, followed by deionized

water, 10% nitric acid solution, and finally with two

rinses of deionized water. Under no circumstance

should chromic acid cleaning be used. It is best

if glassware used for the analysis of Cr(VI) is reserved

for this analysis only, so that the maximum sensitivity,

and lack of outside interference can be obtained.

3.3.2 The stock standard solutions of 100 g/mL

Cr(VI) are prepared by dissolving 0.2828 g of

K2Cr2O7 or 0.3735 g of

K2CrO4 in 1 L of deionized water.

(Prepare solution every 3 months.) Two separate stock

solutions should be prepared, from separate sources, and

used to make the dilutions. All dilutions of the stock

solutions are made with DBE/PBM solution to obtain a

working range of 0.3 to 500 ng/mL. Prepare dilutions

monthly. (For example the stock calculation is: (0.2828 g

K2Cr2O7/liter) × (1000

mg/g) × (1000 g/mg) × (L/1000mL) × (MW Cr/MW

K2Cr2O7 = 51.996/294.18)

× (2 moles of Cr in

K2Cr2O7) = 100 g/mL

Cr(VI).)

3.3.3 Bracket sample concentrations with

standard concentrations. If upon analysis, sample

concentrations fall outside the range of prepared

standards, prepare and analyze additional standards to

confirm instrument response, or dilute high samples with

DBE/PBM solution and reanalyze the diluted samples.

3.4 Sample preparation

3.4.1 Wash all glassware in hot water with

detergent, rinse with tap water, deionized water, 10%

nitric acid solution, and finally with two rinses of

deionized water. Under no circumstances should

chromic acid cleaning be used. If possible, this

glassware should be reserved for the analysis of Cr(VI)

only.

3.4.2 Adjust the hotplate temperature to

below the boiling point of the BE solution, near 135°C.

3.4.3 Remove the filter from the vial and place

face or interior of the folds side down in a labeled 50-mL

Erlenmeyer flask. Add 1.5 mL of PBM solution, swirl to wet

the filter, then add 5 mL of BE solution and mix well

before proceeding to the next sample. It is important to

add the PBM solution first, as the freshly precipitated

magnesium hydroxide that forms upon the addition of the BE

solution, suppresses interference from the other metal

ions. This precipitation happens immediately on mixing, so

it is important that all sides of the filter be wetted.

Heat the samples on the hotplate for 60 to 90 minutes,

watching carefully to prevent the samples from boiling or

evaporating to dryness. If the samples boil or evaporate

to dryness the Cr(VI) will change to Cr(III) affecting the

results.

3.4.4 Allow the samples to cool to room

temperature. Quantitatively transfer each solution to a

10-mL volumetric flask using deionized water, and bring up

to the mark with deionized water. Allow the samples to sit

for 1 hour to allow the precipitate to settle, or

centrifuge at 3200 rpm for 5 to 10 minutes. Carefully

transfer the supernatant to the autosampler vial, and make

sure that none of the precipitate is transferred. The

precipitate will clog the IC.

3.4.5 For wipe

samples of paints, a second extraction of the filter, with

a stronger base solution, will be necessary to get the

Cr(VI) out of the solidified paint. The two extractions

are prepared separately, and analyzed separately. The

analytical results of this second extraction are added to

the first extraction to obtain the final result. Again add

1.5 mL of PBM solution to the Erlenmeyer flask, followed

by the SPE solution, mix well and heat on the hotplate 60

to 90 minutes. Cool to room temperature, then

quantitatively transfer the sample to a 25-mL volumetric

flask with deionized water, and bring up to the mark with

deionized water. Allow the samples to sit 1 hour to allow

the precipitate to settle, or centrifuge at 3200 rpm for 5

to 10 minutes. Carefully transfer the supernatant to an

autosampler vial. 3.5 Analysis

3.5.1 Analytical conditions

| IC conditions |

|

| columns: |

IonPac AS7 column,

250-mm × 4-mm i.d. and IonPac NG-1 guard column

50-mm × 4-mm i.d. at ambient temperature |

| flow rate: |

0.7 mL/min |

| eluent: |

250 mM

(NH4)2SO4 with 100

mM NH4OH |

| pump pressure: |

1000 psi |

| postcolumn

derivatization |

|

| solution: |

0.34 mL/min of 2.0 mM

DPC in 90:10 of 1 N

H2SO4:methyl alcohol |

| UV detector: |

540 nm |

| injection size: |

100 L |

| retention

time: |

6.6 min |

| output range: |

0.1 absorbance unit

full scale (AUFS) |

| chromatogram: |

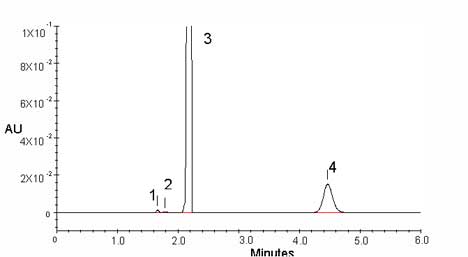

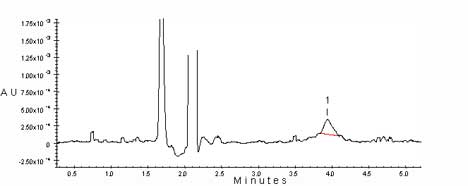

|

Figure 3.5.1.

Chromatogram of an analytical standard of 50 ng/mL

Cr(VI).(1 and 2= solvent peaks, 3=carbon dioxide

from reaction of buffer and derivatizing solution, 4=

Cr(VI))a

3.5.2 An

external standard (ESTD) calibration procedure is used to

prepare a calibration curve using at least 2 stock

standards, from separate sources, from which dilutions are

made. The calibration curve is prepared daily. The samples

are bracketed with analytical standards.

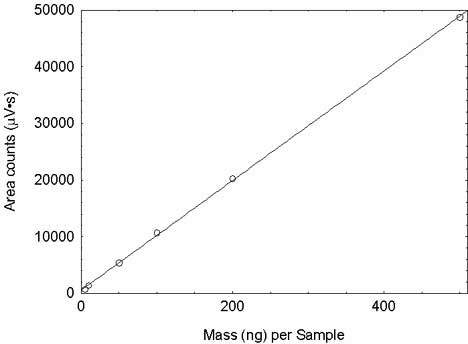

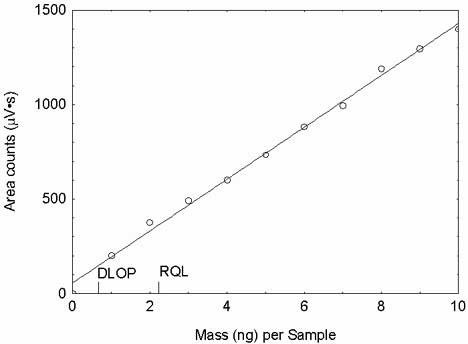

Figure 3.5.2.

Calibration curve of Cr(VI). (Y = 96.7X + 582)

3.6

Interferences (analytical)

3.6.1 Any compound that produces a UV response

and has a similar retention time as Cr(VI) is a potential

interference. If any potential interferences are reported,

they should be considered before samples are extracted.

Generally, chromatographic conditions can be altered to

separate an interference from the analyte.

3.6.2

When necessary, the identity of an analyte peak may be

confirmed with additional analytical data. The possibility

of a coeluting species which does not react with the DPC,

can be tested by injecting the sample with no postcolumn

derivatizing agent being added.

3.6.3 The acid

used in chrome plating operations is an interference.

3.7 Calculations

The amount of

Cr(VI) per sampler is obtained from the appropriate

calibration curve in terms of nanograms per sample,

uncorrected for extraction efficiency. This amount is then

adjusted by subtracting the amount (if any) found on the

blank and corrected for extraction efficiency using the

following formula. If samples were paint samples the results

second extraction of the filter was are also calculated with

the following formula, then both results are added together.

|

|

where |

Ms is the mass recovered from

the sampled surface (µg) |

| |

M is

nanograms per sample |

| |

MB is the mass found on the

blank (ng) |

| |

EE is extraction efficiency, in

decimal form |

| |

CF is

conversion factor of µg/1000

ng | This amount may be expressed as µg Cr(VI) per

100 cm2 if the surface area that was sampled was

provided, by using the following formula.

|

where |

Cs is (µg) of Cr(VI) per 100

cm2 |

|

Ms

is mass on the sampled surface (µg) |

|

S is surface

area sampled (cm2) |

|

100

cm2 is one hundred cubic

centimeters | The surface that was sampled may be less ideal

(more porous, less smooth) than the surface that was used to

evaluate the removal efficiency of the sampling media. In

this circumstance, the media will remove the surface

contaminant less effectively. There may be significant

amounts of contaminant remaining on the surface after

sampling. Nevertheless, the amount found in the sample

indicates that at least this amount of Cr(VI) was present on

the surface. 4.

Backup Data

General

background information about the determination of detection

limits and reproducibility of the overall procedure is found

in the "Evaluation Guidelines for Surface Sampling

Methods".(19)

The Guidelines define analytical parameters, specific

laboratory tests, statistical calculations and acceptance

criteria.

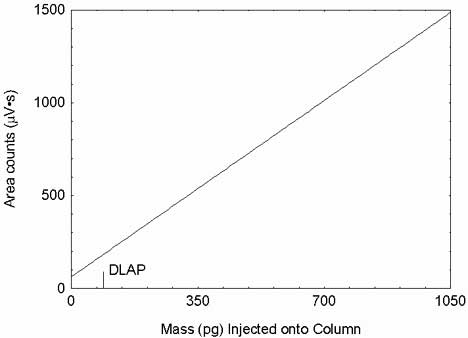

4.1 Detection limit of the analytical procedure

(DLAP) The DLAP was calculated to be 90 picograms per

injection. This is the lowest amount of analyte that will

give a detector response that is significantly different

from the response of a reagent blank. The standards were

prepared in equally descending amounts of 100 picograms from

1000 to 0 picograms, such that the lowest standard had a

peak at least ten times the baseline noise.

Table 4.1

1500 Detection Limit of

the Analytical Procedure |

|

| Mass

Injected (pg) |

area

counts

(µV-s) |

|

| 0 |

0 |

| 100 |

215 |

| 200 |

386 |

| 300 |

509 |

| 400 |

629 |

| 500 |

728 |

| 600 |

831 |

| 700 |

960 |

| 800 |

1169 |

| 900 |

1295 |

| 1000 |

1428 |

|

Figure 4.1.

Plot of the data used to determine the DLAP (Y = 1.36X +

63).

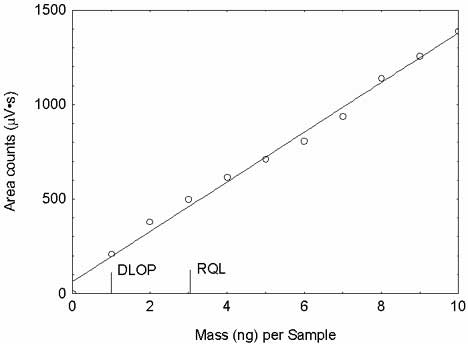

4.2 Detection limit

of the overall procedure (DLOP) and reliable quantitation

limit (RQL)

PVC filters

The DLOP is

measured as mass per sample. Ten PVC filters were spiked

with equal descending increments of analyte, such that the

highest sampler loading was 10 ng/sample. These spiked

samplers, and a sample blank were analyzed with the

recommended analytical parameters, and the data obtained

used to calculate the required parameters (standard error of

estimate and the slope) for the calculation of the DLOP.

Values of 131.6 and 40.0 were obtained for the slope and

standard error of estimate respectively. The DLOP was

calculated to be 0.911 ng/sample.

Table 4.2.1

Detection Limit

of

the Overall Procedure |

|

| mass per

sample (ng) |

area

counts

(µV-s) |

|

| 0 |

0 |

| 1 |

209 |

| 2 |

379 |

| 3 |

498 |

| 4 |

615 |

| 5 |

710 |

| 6 |

806 |

| 7 |

938 |

| 8 |

1140 |

| 9 |

1256 |

| 10 |

1386 |

| The RQL is considered the lower limit for

precise quantitative measurements. It is determined from the

regression line parameters obtained for the calculation of

the DLOP, providing 75% to 125% of the analyte is recovered.

The RQL is 3.04 ng per sample. Recovery at this

concentration is 95.1%.

Figure

4.2.1. Plot of dat to determine the DLOP/RQL for PVC

filters. (Y = 132X + 63.7)

Figure 4.2.2.

Plot of the RQL. (The large peaks that are off scale

are carbon dioxide from the reaction of the buffer with

derivatizing solution. 1 = Cr(VI))

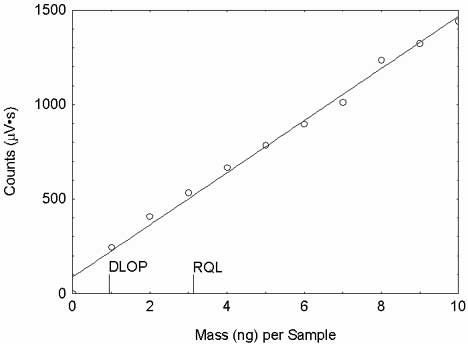

Binderless quartz fiber filters

The

DLOP for the binderless quartz fiber filters was determined

by spiking ten samplers with equal descending increments of

analyte, such that the highest sampler loading was 10

ng/sample. These spiked samplers, and a sample blank were

analyzed with the recommended analytical parameters, and the

data obtained used to calculate the required parameters

(standard error of estimate and the slope) for the

calculation of the DLOP. Values of 137.2 and 56.0 were

obtained for the slope and standard error of estimate

respectively. The DLOP was calculated to be 0.67

ng/sample.

The RQL is considered the lower

limit for precise quantitative measurements. It is

determined from the regression line parameters obtained for

the calculation of the DLOP, providing 75% to 125% of the

analyte is recovered. The RQL is 2.23 ng per sample.

Recovery at this concentration is 94.6%.

Table 4.2.2

Detection Limit of the

Overall Procedure

Binderless Quartz Fiber

Filter |

|

| mass per

sample (ng) |

area

counts

(µV-s) |

|

| 0 |

0 |

| 1 |

201 |

| 2 |

376 |

| 3 |

491 |

| 4 |

602 |

| 5 |

712 |

| 6 |

813 |

| 7 |

943 |

| 8 |

1144 |

| 9 |

1255 |

| 10 |

1399 |

|

Figure 4.2.3.

Plot of the data used to determine the DLOP/RQL for

binderless quartz fiber filters (Y = 137X + 56).

1% NaOH Coated

Blinderless Quartz Fiber Filters

The

DLOP for the 1% NaOH coated binderless quartz fiber filters

was determined by spiking ten samplers with equal descending

increments of analyte, such that the highest sampler loading

was 10 ng/sample. These spiked samplers, and a sample blank

were analyzed with the recommended analytical parameters,

and the data obtained used to calculate the required

parameters (standard error of estimate and the slope) for

the calculation of the DLOP. Values of 138 and 87.1 were

obtained for the slope and standard error of estimate

respectively. The DLOP was calculated to be 0.937

ng/sample.

The RQL is considered the lower

limit for precise quantitative measurements. It is

determined from the regression line parameters obtained for

the calculation of the DLOP, providing 75% to 125% of the

analyte is recovered. The RQL is 3.12 ng per sample.

Recovery at this concentration is 96.8%.

Table 4.2.3

Detection Limit of the

Overall Procedure

1% NaOH coated Binderless

Quartz Fiber Filter |

|

mass per

sample

(ng) |

area

counts

(µV-s) |

|

| 0 |

0 |

| 1 |

245 |

| 2 |

408 |

| 3 |

534 |

| 4 |

667 |

| 5 |

786 |

| 6 |

897 |

| 7 |

1011 |

| 8 |

1234 |

| 9 |

1324 |

| 10 |

1439 |

|

Figure 4.2.4.

Plot of the data used to determine the DLOP/RQL for 1% NaOH

coated binderless quartz fiber filters (Y = 138X + 87.1).

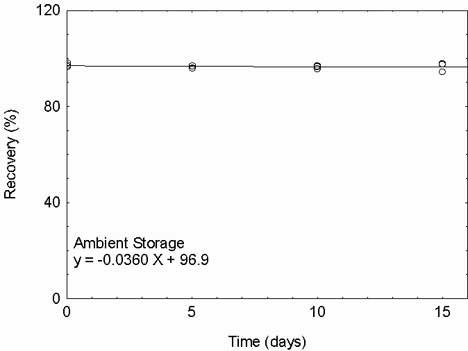

4.3 Storage tests

Cr(VI) spiked on PVC filters

Storage

samples were prepared by spiking PVC filters with Cr(VI).

The PVC filter was spiked with the target concentration of

Cr(VI) and allowed to dry. Twenty-one storage samples were

prepared. Three samples were analyzed on the day of

preparation. Nine of the filters were stored at reduced

temperature (4ºC) and the other nine were stored in a closed

drawer at ambient temperature (about 22ºC). At 5-day

intervals, three samples were selected from each of the two

storage sets and analyzed. Sample results were not corrected

for extraction efficiency. The recoveries at Day 15 were

96.4% at ambient and refrigerated temperature.

Table 4.3.1

Storage Test for Cr(VI) on

PVC Filters |

|

| time

(days) |

ambient storage recovery (%) |

refrigerated storage recovery (%) |

|

| 0 |

98.0 |

97.8 |

97.2 |

98.0 |

97.8 |

97.2 |

| 5 |

96.9 |

95.9 |

96.0 |

96.7 |

97.4 |

95.6 |

| 10 |

95.8 |

96.9 |

96.7 |

97.1 |

98.8 |

95.1 |

| 15 |

97.8 |

97.6 |

94.5 |

95.2 |

96.4 |

97.3 |

|

Figure 4.3.1.

Ambient storage test for Cr(VI) spiked on PVC filters.

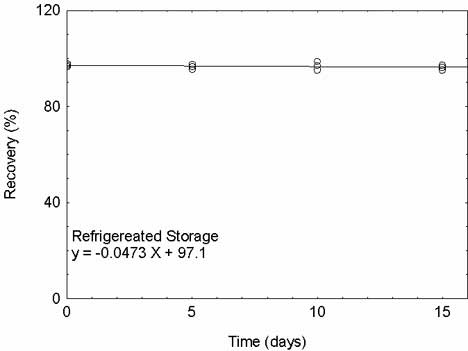

Figure 4.3.2.

Refrigerated storage test for Cr(VI) spiked on PVC filters.

Cr(VI) spiked on

binderless quartz fiber filters.

Storage samples

were prepared by spiking binderless quartz fiber filters

with Cr(VI). The binderless quartz fiber filter was spiked

with the target concentration of Cr(VI) and allowed to dry.

Twenty-one storage samples were prepared. Three samples were

analyzed on the day of preparation. Nine of the filters were

stored at reduced temperature (4ºC) and the other nine were

stored in a closed drawer at ambient temperature (about

22ºC). At 5-day intervals, three samples were selected from

each of the two storage sets and analyzed. Sample results

were not corrected for extraction efficiency. The recoveries

at Day 15 were 96.4% at ambient temperature and 96.2% at

refrigerated temperature.

Table 4.3.2

Storage Test for Cr(VI) on

Binderless Quartz Fiber Filters |

|

| time

(days) |

ambient storage recovery (%) |

refrigerated storage recovery (%) |

|

| 0 |

98.2 |

98.1 |

97.1 |

98.2 |

97.1 |

98.3 |

| 5 |

97.9 |

96.1 |

96.7 |

97.1 |

97.9 |

96.7 |

| 10 |

96.1 |

96.6 |

97.2 |

97.3 |

98.2 |

96.1 |

| 15 |

97.3 |

97.2 |

95.1 |

96.1 |

96.3 |

95.3 |

|

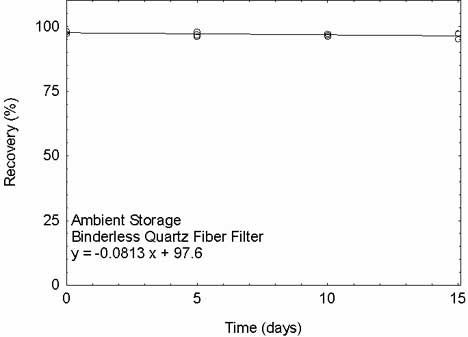

Figure 4.3.3.

Ambient storage test for Cr(VI) spiked on binderless quartz

fiber filters.

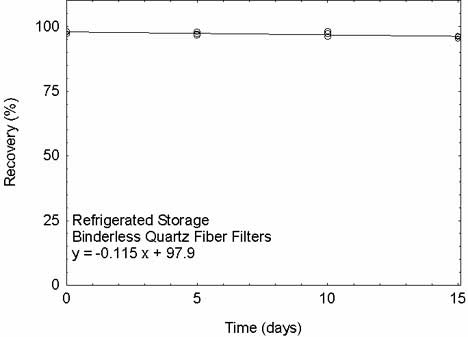

Figure 4.3.4.

Refrigerated storage test for Cr(VI) spiked on binderless

quartz fiber filters.

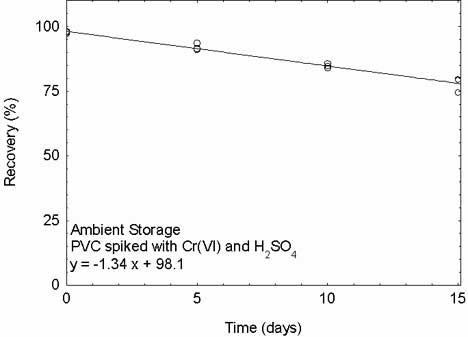

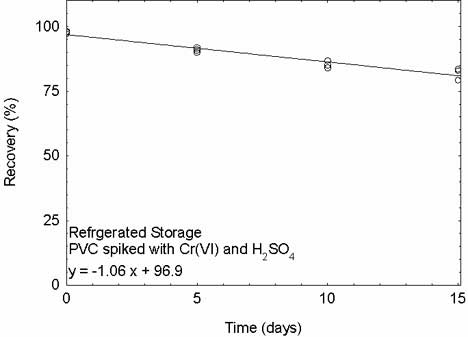

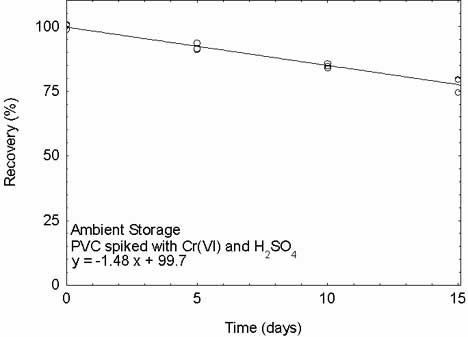

Cr(VI) and H2SO4

spiked on PVC filters

In chrome plating

environments the presence of acid causes a negative

interference due to reaction between the Cr(VI) and acid to

form Cr(III). Most chrome plating baths contain

H2S04 so a mixture of

H2S04 and Cr(VI) was prepared in water

to spike the filters with. Storage samples were prepared by

spiking PVC filters with Cr(VI) and

H2S04. The PVC filter was spiked with

50 ng of Cr(VI) and 0.5 ng H2SO4 and

allowed to dry. Twenty-one storage samples were prepared.

Three samples were analyzed on the day of preparation. Nine

of the filters were stored at reduced temperature (4ºC) and

the other nine were stored in a closed drawer at ambient

temperature (about 22ºC). At 5-day intervals, three samples

were selected from each of the two storage sets and

analyzed. There was an immediate reaction between the Cr(VI)

and the sulfuric acid, causing some of the Cr(VI) to change

to Cr(III). Results were corrected for this bias. The

results show a recovery of 78.0% on day 15 for samples

stored at ambient temperature, and 81.0% for refrigerated

samples.

Table 4.3.3

Storage Test for

Cr(VI) and H2S04 on PVC

Filters |

|

| time (days) |

refrigerated storage recovery (%) |

refrigerated storage recovery (%) |

|

| 0 |

100.5 |

98.8 |

100.7 |

100.5 |

98.8 |

100.7 |

| 5 |

91.1 |

91.5 |

93.6 |

90.0 |

90.9 |

91.7 |

| 10 |

85.8 |

83.9 |

84.7 |

84.1 |

86.8 |

85.1 |

| 15 |

74.5 |

79.4 |

79.5 |

79.3 |

83.5 |

82.9 |

|

Figure 4.3.5.

Ambient storage test for Cr(VI) and

H2SO4 spiked on PVC filters.

Figure 4.3.6.

Refrigerated storage test for Cr(VI) and

H2SO4 spiked on PVC filters.

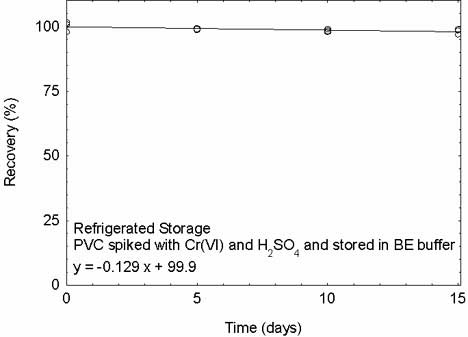

Cr(VI) and

H2S04 spiked on PVC filters placed

immediately in 5 mL of an aqueous solution containing 10%

Na2CO3 with 2% NaHCO3

The "Evaluation Guidelines for Surface Sampling

Methods" states that a drop in recovery of greater than 10%

upon storage for 15 days is a significant uncorrectable

bias, and should be avoided.(20)

The recoveries for the PVC filters spiked with Cr(VI)

and H2S04 on day 15 were 78.0% for

ambient and 81.0% for refrigerated samples. To eliminate

this negative bias from the H2S04, the

PVC filters were spiked with Cr(VI) and

H2S04 and then placed into a vial

containing 5 mL of an aquerous solution containing 10%

Na2CO3 with 2% NaHCO3 (BE

buffer) immediately. The PVC filter was spiked with 50 ng of

Cr(VI) and 0.5 ng H2S04. Twenty-one

storage samples were prepared.

Three samples

were analyzed on the day of preparation. Nine of the filters

were stored at reduced temperature (4ºC) and the other nine

were stored in a closed drawer at ambient temperature (about

22ºC). At 5-day intervals, three samples were selected from

each of the two storage sets and analyzed. There was an

immediate reaction between the Cr(VI) and the sulfuric acid,

causing some of the Cr(VI) to change to Cr(III). Results

were corrected for this bias. The recoveries on day 15

were 97.4% for ambient, and 98.0% for refrigerated.

Table 4.3.4

Storage Test for Cr(VI) and

H2SO4

on PVC Filters

and Placed in BE Buffer |

|

| time

(days) |

ambient storage recovery (%) |

refrigerated storage recovery (%) |

|

| 0 |

100.7 |

97.9 |

101.5 |

100.7 |

97.9 |

101.5 |

| 5 |

99.6 |

96.9 |

98.9 |

99.2 |

98.9 |

99.1 |

| 10 |

98.4 |

97.6 |

97.9 |

97.9 |

98.4 |

99.0 |

| 15 |

98.9 |

95.6 |

98.3 |

98.5 |

98.9 |

96.9 |

|

Figure 4.3.7.

Ambient storage test for Cr(VI) and

H2SO4 spiked on PVC filters and stored

in 5 mL BE buffer.

Figure 4.3.8.

Refrigerated storage test for Cr(VI) and

H2SO4 spiked on PVC filters and stored

in 5 mL BE buffer.

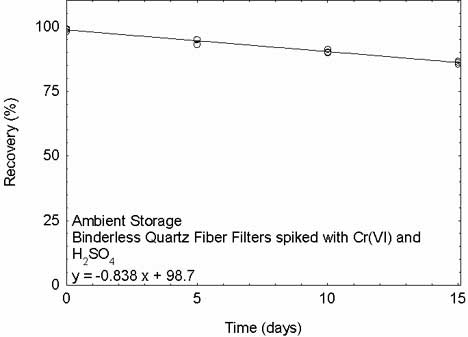

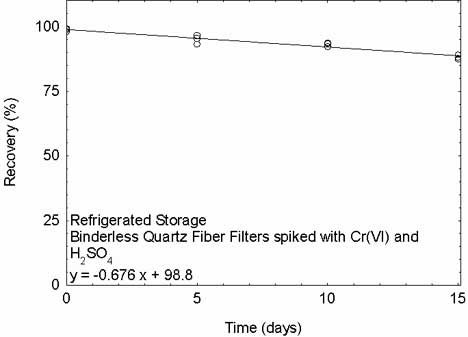

Cr(VI)

and H2S04 spiked on binderless quartz

fiber filters

Binderless quartz fiber filters were

spiked with a mixture of H2S04 and

Cr(VI) in water at concentration of 50 ng Cr(VI) and 0.5 ng

H2S04 and allowed to dry. Twenty-one

storage samples were prepared. Three samples were analyzed

on the day of preparation. Nine of the filters were stored

at reduced temperature (4ºC) and the other nine were stored

in a closed drawer at ambient temperature (about 22ºC). At

5-day intervals, three samples were selected from each of

the two storage sets and analyzed. There was an immediate

reaction between the Cr(VI) and the sulfuric acid, causing

some of the Cr(VI) to change to Cr(Ill). Results were

corrected for this bias. The results show a recovery

of 86.1 % on day 15 for samples stored at ambient

temperature, and 88.7% for refrigerated samples.

Table 4.3.5

Storage Test for Cr(VI) and

H2S04

on Binderless

Quartz Fiber Filters |

|

| time

(days) |

ambient storage recovery (%) |

refrigerated storage recovery (%) |

|

|

|

|

| 0 |

100.9 |

99.3 |

99.8 |

100.9 |

99.3 |

99.8 |

| 5 |

94.8 |

93.0 |

95.1 |

96.4 |

93.2 |

95.4 |

| 10 |

90.1 |

91.2 |

89.9 |

93.7 |

92.2 |

93.4 |

| 15 |

85.4 |

86.8 |

86.1 |

87.9 |

89.2 |

87.3 |

|

. Figure 4.3.9.

Ambient storage test for Cr(VI) and

H2SO4 spiked on binderless quartz

fiber filters.

Figure 4.3.10.

Refrigerated storage test for Cr(VI) and

H2SO4 spiked on binderless quartz

fiber filters.

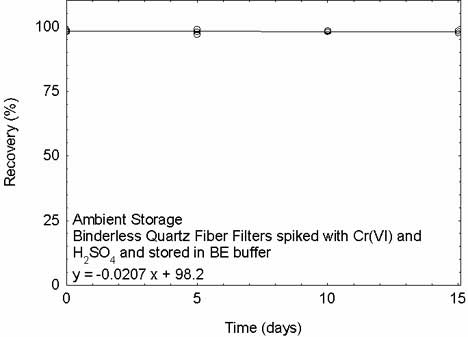

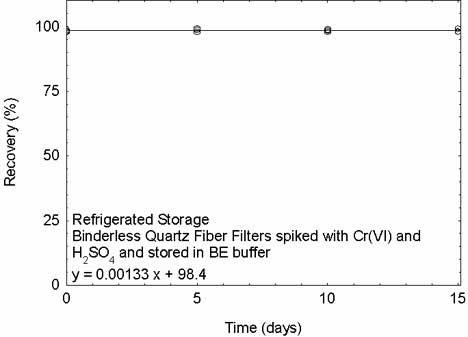

Cr(VI) and

H2S04 spiked on binderless quartz

fiber filter placed immediately in 5 mL of a solution

containing 10% Na2CO3 with 2%

NaHCO3

Because the recoveries for

the binderless quartz fiber filters spiked with the mixture

of Cr(VI) and H2S04 was 86.1 % on day

15 for samples stored at ambient temperature, and 88.7% for

refrigerated samples, placing the filters into 5 mL of an

aqueous solution containing 10% Na2CO3 with 2%

NaHCO3 (BE buffer) immediately after spiking was

performed. The binderless quartz fiber filter was spiked

with 50 ng of Cr(VI) and 0.5 ng H2S04.

Twenty-one storage samples were prepared. Three samples were

analyzed on the day of preparation. Nine of the filters were

stored at reduced temperature (4ºC) and the other nine were

stored in a closed drawer at ambient temperature (about

22ºC). At 5-day intervals, three samples were selected from

each of the two storage sets and analyzed. There was an

immediate reaction between the Cr(VI) and the sulfuric acid,

causing some of the Cr(VI) to change to Cr(Ill). Results

were corrected for this bias. The recoveries on day 15

were 97.9% for ambient and 98.4% for refrigerated samples.

Table 4.3.6

Storage Test for Cr(VI) and

H2S04

on Binderless

Quartz Fiber Filters and Placed in BE Buffer |

|

| time

(days) |

ambient storage recovery (%) |

refrigerated storage recovery (%) |

|

| 0 |

100.8 |

99.9 |

99.3 |

100.8 |

99.9 |

99.3 |

| 5 |

96.9 |

97.9 |

98.9 |

98.8 |

97.9 |

99.3 |

| 10 |

98.4 |

98.5 |

97.9 |

97.9 |

98.9 |

98.5 |

| 15 |

98.3 |

97.5 |

97.6 |

99.1 |

98.1 |

97.9 |

|

Figure 4.3.11.

Ambient storage test for Cr(VI) and

H2SO4 spiked on binderless quartz

fiber filters and stored in 5 mL BE buffer.

Figure 4.3.12.

Refrigerated storage test for Cr(VI) and

H2SO4 spiked on binderless quartz

fiber filters and stored in 5 mL BE buffer.

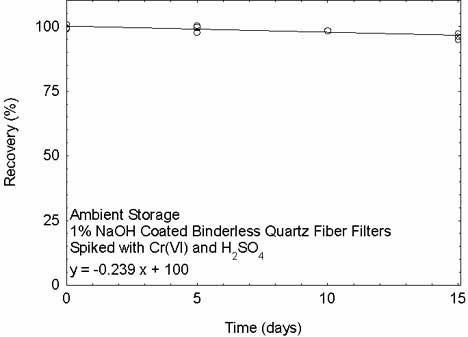

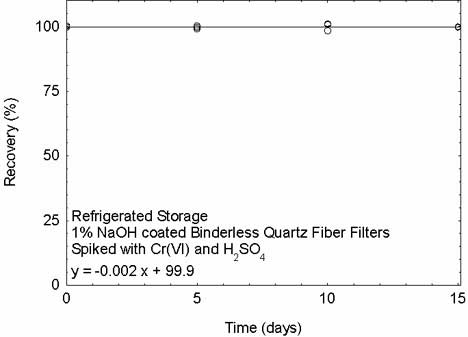

Cr(VI) and

H2S04 spiked on 1% NaOH coated

binderless quartz fiber filter

Storage samples

were prepared by spiking 1% NaOH coated binderless quartz

fiber filters with 50 ng Cr(VI) and 0.5 ng

H2S04 and allowed to dry. Twenty-one

storage samples were prepared. Three samples were analyzed

on the day of preparation. Nine of the filters were stored

at reduced temperature (4ºC) and the other nine were stored

in a closed drawer at ambient temperature (about 22ºC). At

5-day intervals, three samples were selected from each of

the two storage sets and analyzed. On Day 15 the recovery

was 96.4% for samples stored at ambient temperature and 96.1

% for samples stored at refrigerated temperature.

Table 4.3.7

Storage Test for Cr(VI) and

H2SO4

on 1 % NaOH Coated binderless Quartz

Fiber Filters |

|

| time

(days) |

ambient storage recovery (%) |

refrigerated storage recovery (%) |

|

| 0 |

100.3 |

99.2 |

99.4 |

100.3 |

99.2 |

99.4 |

| 5 |

97.7 |

99.6 |

100.3 |

99.5 |

97.7 |

98.1 |

| 10 |

98.3 |

98.4 |

98.4 |

98.6 |

95.7 |

97.9 |

| 15 |

94.9 |

97.4 |

96.1 |

96.4 |

95.4 |

96.1 |

|

Figure 4.3.13.

Ambient storage test for Cr(VI) and

H2SO4 spiked on 1% NaOH coated

binderless quartz fiber filters.

Figure 4.3.14.

Refrigerated storage test for Cr(VI) and

H2SO4 spiked on 1% NaOH coated

binderless quartz fiber filters.

4.4 Sampler removal efficiency

4.4.1 Removal efficiency refers to the ability

of the PVC filters to absorb or otherwise capture surface

contaminants when the filter is moved across a surface

under firm pressure. The surface used to evaluate the

removal efficiency was a PTFE sheet. This type of surface

approaches the smooth and non-porous characteristics of an

ideal surface. The variety of surfaces found in workplaces

will likely be less than ideal, so the media will have a

lower removal efficiency. The amount of analyte found on

the filter after sampling will indicate that at least that

amount was present on the surface that was sampled. Six

surfaces were spiked at the target concentration of

Cr(VI), 0.05 µg/100 cm2. Samples were collected

from each surface using the technique described in Section

2.3 and analyzed. The results are shown in Table 4.4.1.

Table 4.4.1

Sampler Removal Efficiency

Data for Cr(VI) from PTFE using PVC Filters |

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

| 0.05 |

0.0490 |

98.0 |

| 0.05 |

0.0491 |

98.2 |

| 0.05 |

0.0488 |

97.6 |

| 0.05 |

0.0476 |

95.2 |

| 0.05 |

0.0479 |

95.8 |

| 0.05 |

0.0482 |

96.4 |

|

4.4.2 Removal efficiency of binderless

quartz fiber filters was determined by placing the Cr(Vl)

on a PTFE sheet. This type of surface approaches the

smooth and non-porous characteristics of an ideal surface.

The variety of surfaces found in workplaces, including

theoretical recovered recovery skin, will likely be less

than ideal. The media will have a lower removal efficiency

on less ideal surfaces. The amount of analyte found on the

filter after sampling will indicate that at least that

amount was present on the surface that was sampled. Six

surfaces were spiked at the target concentration of

Cr(VI), 0.05 µg/100 cm2. Samples were collected

from each surface using the technique described in Section

2.3 and analyzed. The results are shown in Table 4.4.2.

Table 4.4.2

Sampler Removal

Efficiency Data

for Cr(VI) from PTFE

using

Binderless Quartz Fiber Filters |

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

| 0.05 |

0.0489 |

97.8 |

| 0.05 |

0.0493 |

98.6 |

| 0.05 |

0.0492 |

98.4 |

| 0.05 |

0.0483 |

96.6 |

| 0.05 |

0.0484 |

96.8 |

| 0.05 |

0.0489 |

97.8 |

|

4.4.3 Removal efficiency of 1% NaOH coated

binderless quartz fiber filters was determined by placing

the Cr(Vl) on a PTFE sheet. This type of surface

approaches the smooth and non-porous characteristics of an

ideal surface. The variety of surfaces found in

workplaces, including skin, will likely be less than

ideal. The media will have a lower removal efficiency on

less ideal surfaces. The amount of analyte found on the

filter after sampling will indicate that at least that

amount was present on the surface that was sampled. Six

surfaces were spiked at the target concentration of

Cr(VI), 0.05 µg/100 cm2. Samples were collected

from each surface using the technique described in Section

2.3 and analyzed. The results are shown in Table 4.4.3.

Table 4.4.3

Sampler Removal

Efficiency

Data for Cr(VI) from

PTFE

using NaOH Coated Binderless Quartz

Fiber Filters |

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

| 0.05 |

0.0487 |

97.4 |

| 0.05 |

0.0493 |

98.6 |

| 0.05 |

0.0482 |

96.4 |

| 0.05 |

0.0483 |

96.6 |

| 0.05 |

0.0475 |

95.0 |

| 0.05 |

0.0491 |

98.2 |

|

4.4.4 Removal efficiency shall be calculated

as follows:

| where |

ER

is removal efficiency |

|

AR

is amount of analyte recovered |

|

AS is amount of analyte spiked

on the

surface |

The mean removal efficiency of the six

samples was 96.9% for PVC filters, 97.7% for binderless

quartz fiber filters, and 97.0% for 1% NaOH coated

binderless quartz fiber filters. 4.5 Extraction efficiency

The

extraction efficiencies of Cr(VI) were determined by

liquid-spiking PVC filters with Cr(VI) at concentrations

ranging from the RQL (0.06) to 10 times the target

concentration. These samples were stored overnight at

ambient temperature and then analyzed. The filters were

either extracted and digested with the first, main

extraction solution, BE, or with the second, spray paint

only, SPE solution. The mean extraction efficiency over the

working range of the RQL to 10 times the target

concentration is 96.6% for samples extracted with the first

(main) extraction solvent (BE) and 96.9% for samples

extracted with the second extraction solvent for paint

samples (SPE).

Table 4.5.1

Extraction Efficiency of

Cr(VI)

from PVC Filters Extracted with

BE |

|

level

|

sample number

|

| × target

concn |

ng per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3 |

95.4 |

96.6 |

92.7 |

95.5 |

95.1 |

| 0.1 |

5 |

96.4 |

96.5 |

97.9 |

95.9 |

96.7 |

| 1.0 |

50 |

97.8 |

97.2 |

96.7 |

97.6 |

97.3 |

| 10.0 |

500 |

97.4 |

97.8 |

97.0 |

96.1 |

97.1 |

|

Table 4.5.2

Extraction Efficiency of

Cr(VI)

from PVC Filters Extracted with

SPE |

|

level

|

sample number

|

| × target

concn |

ng per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3 |

97.8 |

95.0 |

97.3 |

95.5 |

96.4 |

| 0.1 |

5 |

97.5 |

97.1 |

97.6 |

96.0 |

97.1 |

| 1.0 |

50 |

95.9 |

97.5 |

96.3 |

96.1 |

96.5 |

| 10.0 |

500 |

98.0 |

96.4 |

97.1 |

97.9 |

97.4 |

| The extraction efficiencies of Cr(VI) were

determined by liquid-spiking binderless quartz fiber filters

with Cr(VI) at concentrations ranging from the RQL (0.06) to

10 times the target concentration. These samples were stored

overnight at ambient temperature and then analyzed. The

filters were either extracted and digested with the first,

main extraction solution, BE, or with the second, spray

paint only, SPE solution. The mean extraction efficiency

over the working range of the RQL to 10 times the target

concentration is 97.3% for samples extracted with the first

(main) extraction solvent (BE) and 96.2% for samples

extracted with the second extraction solvent for paint

samples (SPE).

Table 4.5.3

Extraction Efficiency of

Cr(VI)

from Binderless Quartz Fiber Filters

Extracted with BE |

|

level

|

sample number

|

| × target

concn |

ng per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3 |

96.3 |

95.4 |

95.9 |

96.3 |

96.0 |

| 0.1 |

5 |

97.2 |

96.9 |

96.8 |

97.5 |

97.1 |

| 1.0 |

50 |

98.4 |

97.2 |

98.2 |

97.9 |

97.9 |

| 10.0 |

500 |

97.9 |

98.3 |

98.1 |

98.1 |

98.1 |

|

Table 4.5.4

Extraction Efficiency of

Cr(VI)

from Binderless Quartz Fiber Filters

Extracted with SPE |

|

level

|

sample number

|

| × target

concn |

ng per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3 |

96.1 |

95.3 |

95.7 |

96.2 |

95.8 |

| 0.1 |

5 |

97.2 |

96.7 |

96.8 |

95.8 |

96.6 |

| 1.0 |

50 |

97.4 |

96.3 |

95.9 |

95.0 |

96.2 |

| 10.0 |

500 |

96.3 |

95.2 |

97.2 |

96.5 |

96.3 |

| The extraction efficiencies of Cr(VI) were

determined by liquid-spiking 1% NaOH coated binderless

quartz fiber filters with Cr(VI) at concentrations ranging

from the RQL (0.06) to 10 times the target concentration.

These samples were stored overnight at ambient temperature

and then analyzed. The filters were either extracted and

digested with the first, main extraction solution, BE, or

with the second, spray paint only, SPE solution. The mean

extraction efficiency over the working range of the RQL to

10 times the target concentration is 97.3% for samples

extracted with the first (main) extraction solvent (BE) and

96.9% for samples extracted with the second extraction

solvent for paint samples (SPE).

Table 4.5.5

Extraction Efficiency

of Cr(VI) from 1 % NaOH

Coated Binderless

Quartz Fiber Filters Extracted with BE |

|

level

|

sample number

|

| × target

concn |

ng per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3 |

97.4 |

95.3 |

97.1 |

96.2 |

96.5 |

| 0.1 |

5 |

96.3 |

97.1 |

96.9 |

97.4 |

96.9 |

| 1.0 |

50 |

98.1 |

95.9 |

98.1 |

98.2 |

97.6 |

| 10.0 |

500 |

97.7 |

98.1 |

97.9 |

98.3 |

98.0 |

|

Table 4.5.6

Extraction Efficiency

of Cr(VI) from 1 % NaOH

Coated Binderless

Quartz Fiber Filters Extracted with SPE |

|

level

|

sample number

|

| × target

concn |

ng per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3 |

96.9 |

95.9 |

96.3 |

95.4 |

96.1 |

| 0.1 |

5 |

98.1 |

96.8 |

97.7 |

96.4 |

97.0 |

| 1.0 |

50 |

97.9 |

97.5 |

96.8 |

96.5 |

97.2 |

| 10.0 |

500 |

96.9 |

97.2 |

97.9 |

97.5 |

97.4 |

| 4.6 Reproducibility

4.6.1 Six PTFE surfaces were spiked at

the target level of 50 ng Cr(VI). A chemist, other than

the one developing the method, conducted sampling on the

PTFE surfaces as described in Section 2 using PVC filters.

The test was repeated with a second chemist performing the

sampling. The samples were analyzed. The first chemist was

able to achieve a removal efficiency of 96.0% and the

second chemist 95.1% (Tables 4.6.1.1 and 4.6.1.2).

Table 4.6.1.1

Sampling Reproducibility

Sampling 1st Chemist Samples for Cr(VI) from

PTFE using PVC Filters |

|

Table 4.6.1.2

Sampling Reproducibility

Sampling 2nd Chemist Samples for Cr(VI) from

PTFE using PVC Filters |

|

|

|

| theoretical

(ng/surface) |

recovered

(ng/sample) |

recovery

(%) |

|

theoretical

(ng/surface) |

recovered

(ng/sample) |

recovery

(%) |

|

|

|

| 50 |

48.2 |

96.4 |

|

50 |

46.5 |

93.0 |

| 50 |

48.7 |

97.4 |

|

50 |

47.9 |

95.8 |

| 50 |

48.4 |

96.8 |

|

50 |

48.6 |

97.2 |

| 50 |

47.2 |

94.4 |

|

50 |

48.7 |

97.4 |

| 50 |

48.3 |

96.6 |

|

50 |

46.9 |

93.8 |

| 50 |

47.2 |

94.4 |

|

50 |

46.7 |

93.4 |

|

|

|

4.6.2 Six samples were

prepared by spiking PVC filters in the same manner that

was used in the preparation for the storage study. The

samples were submitted to the OSHA SLTC for analysis. The

samples were analyzed after being stored for 13 days at

23ºC. Sample results were corrected for extraction

efficiency. The average recoverywas97.6%.

Table 4.6.2

Analytical

Reprocibility Data for Cr(VI) using PVC

Filters

|

| 50 |

48.1 |

96.2 |

| 50 |

49.2 |

98.4 |

| 50 |

47.9 |

95.8 |

| 50 |

48.6 |

97.2 |

| 50 |

49.1 |

98.2 |

| 50 |

49.8 |

99.6 |

4.6.3 Six PTFE surfaces were spiked at the

target level of 50 ng Cr(VI). A chemist, other than the

one developing the method, conducted sampling on the PTFE

surfaces as described in Section 2 using binderless quartz

fiber filters. The test was repeated with a second chemist

performing the sampling. The samples were analyzed. The

first chemist was able to achieve a removal efficiency of

95.9% and the second chemist 96.0% (Tables 4.6.3.1 and

4.6.3.2).

Table 4.6.3.1

Sampling

Reproducibility 1st Chemist Samples for Cr(VI) from PTFE

using Binderless Quartz Fiber PTFE Filters |

|

Table 4.6.3.2

Sampling

Reproducibility 2nd Chemist Samples for Cr(VI) from PTFE

using Binderless Quartz Fiber PTFE Filters |

|

|

|

| theoretical (ng/surface) |

recovered (ng/sample) |

recovery (%) |

|

theoretical (ng/surface) |

recovered (ng/sample) |

recovery (%) |

|

|

|

| 50 |

47.2 |

94.4 |

|

50 |

47.5 |

95.0 |

| 50 |

48.9 |

97.8 |

|

50 |

48.6 |

97.2 |

| 50 |

47.1 |

94.2 |

|

50 |

48.3 |

96.6 |

| 50 |

47.5 |

95.0 |

|

50 |

48.8 |

97.6 |

| 50 |

48.8 |

97.6 |

|

50 |

47.1 |

94.2 |

| 50 |

48.4 |

96.8 |

|

50 |

47.7 |

95.4 |

|

|

|

4.6.4 Six samples were

prepared by spiking binderless quartz fiber filters in the

same manner that was used in the preparation for the

storage study. The samples were submitted to the

OSHA SLTC for analysis. The samples were analyzed after

being stored for 5 days at 23ºC. Sample results were

corrected for extraction efficiency. The average recovery

was 96.5%.

Table 4.6.4

Analytical Reproducibility

Data

for Cr(VI) using

Binderless

Quartz Fiber Filters |

|

| theoretical (ng/surface) |

recovered

(ng/sample) |

recovery

(%) |

|

| 50 |

47.3 |

94.6 |

| 50 |

48.4 |

96.8 |

| 50 |

47.9 |

95.8 |

| 50 |

48.2 |

96.4 |

| 50 |

48.8 |

97.6 |

| 50 |

48.9 |

97.8 |

|

4.6.5 Six PTFE surfaces were spiked at the

target level of 50 ng Cr(VI). A chemist, other than the

one developing the method, conducted sampling on the PTFE

surfaces as described in Section 2 using 1% NaOH coated

binderless quartz fiber filters. The test was repeated

with a second chemist performing the sampling. The samples

were analyzed. The first chemist was able to achieve a

removal efficiency of 96.0% and the second chemist 96.5%

(Tables 4.6.5.1 and 4.6.5.2).

Table 4.6.5.1

Sampling

Reproducibility

1st Chemist Samples for Cr(VI)

from PTFE using Binderless Quartz Fiber PTFE Filters |

|

Table 4.6.5.2

Sampling

Reproducibility

2nd Chemist Samples for Cr(VI)

from PTFE using Binderless Quartz Fiber PTFE

Filters |

|

|

|

| theoretical (ng/surface) |

recovered (ng/sample) |

recovery (%) |

|

theoretical (ng/surface) |

recovered (ng/sample) |

recovery (%) |

|

|

|

| 50 |

47.9 |

95.8 |

|

50 |

48.9 |

97.8 |

| 50 |

47.8 |

95.6 |

|

50 |

47.2 |

94.4 |

| 50 |

48.2 |

96.4 |

|

50 |

47.7 |

95.4 |

| 50 |

48.7 |

97.4 |

|

50 |

48.8 |

97.6 |

| 50 |

47.9 |

95.8 |

|

50 |

48.9 |

97.8 |

| 50 |

47.5 |

95.0 |

|

50 |

47.9 |

95.8 |

|

|

|

4.6.6 Six samples were

prepared by spiking 1% NaOH coated binderless quartz fiber

filters in the same manner that was used in the

preparation for the storage study. The samples were

submitted to the OSHA SLTC theoretical recovered recovery

for analysis. The samples were analyzed after being stored

for 9 days at 23ºC. Sample results were corrected for

extraction efficiency. The average recovery was 95.8%.

Table 4.6.6

Analytical

Reproducibility Data

for Cr(VI) on NaOH

Coated Binderless Quartz Fiber Filters |

|

| theoretical (ng/surface) |

recovered (ng/sample) |

recovery (%) |

|

| 50 |

47.4 |

94.8 |

| 50 |

48.2 |

96.4 |

| 50 |

48.8 |

97.6 |

| 50 |

47.1 |

94.2 |

| 50 |

47.6 |

95.2 |

| 50 |

48.4 |

96.8 |

| 4.7 Interferences (sampling)

Suspected

interferences should be reported to the laboratory with

submitted samples. The interference studies were performed

in Method ID-215 Hexavalent Chromium, and should be

consulted for specific information about the metal species

of interest(21).

The major positive interference is Cr(III), which can be

oxidized to Cr(VI). The major negative interference is

Fe(II), which can reduce the Cr(VI) to Cr(III). Other

reducing metal species can also change Cr(VI) to

Cr(III).

In chrome plating operations the acid

is a negative interference, and samples taken on PVC or

uncoated binderless quartz fiber filters must be placed into