Purpose: To define the

procedure to prepare pre-weighed filters for use by OSHA IHs and to

describe the procedure to analyze the filters after they have been

returned to the Salt Lake Technical Center (SLTC) for

analysis.

Scope: This standard operating

procedure (SOP) applies to all analysts that are assigned to the

Gravimetric work station or are involved in preparing the filters for use.

| Procedure: The

following describes the step-by-step SOP for weighing filters using

the OSHA Automated Weighing System. The filter media is 37-mm

diameter low-ash polyvinyl chloride (PVC). These preweighed filters

are used by the field compliance officers for the collection of

respirable and nonrespirable particulate material. These PVC filters

in their "flying saucer" type cassette are exclusively recommended

for respirable sampling. An abstract of a memorandum that describes

their use in the field is attached. (Appendix A) The sealed

cassettes with the preweighed and numbered filters are shipped from

the SLTC. |

| The automated weighing system comprises an

environment-controlled chamber, drying ovens, analytical balance, two

automated Zymark robotic systems, and associated computer and network

connections. The Automated Weighing System SOP describes the proper

calibration and use of this instrumentation. These procedures apply in

both the preweighing for a tare weight of the filter and the final

weighing to determine total particulate weight.

- Only authorized laboratory personnel are allowed in the weighing

area. Lock the weighing room after business hours and when not in use.

Challenge any non-laboratory worker entering the weighing area without

an escort.

- The automatic weighing program which utilizes robotics is described

in Appendix B. Appendix B outlines the sequence of events the robot

performs to weigh the filters. Additionally, the software commands that

control the robot are listed. Analysts should refer to Appendix B for

details of the robot’s operation.

- The filters are weighed in a laboratory environmental controlled

room with the temperature being controlled to 21 ± 1ºC (70 ± 2ºF) and

relative humidity to 35 ± 5%. Deviations from these parameters must be

addressed before the weighing of filters. Consult your supervisor or

arrange for repair services to correct the problem.

- Strictly comply with good laboratory practices with no smoking or

eating in the weighing room or laboratory. Before handling filters or

gravimetric samples, work areas should be cleaned with damp towel and

adsorbent pads placed on the bench top. Handle all filters with tweezers

or a gloved hand. Preweighed filters are not handled with bare

hands.

- The PVC filter assemblies are purchased from MSA, Inc. and are

packaged in a plastic sleeve containing 40 assemblies. The filter

assemblies are removed from the sleeves and a bar code is affixed to the

aluminum cone. The assemblies are place on a 75-position weighing rack.

The filters will remain on this rack for the entire weighing process.

Desiccate all filters in a vacuum oven before pre-weighing. The initial

desiccation is under a vacuum (-15 inHg) at 60ºC using a dry air bleed

for a total of 36 hours. Subsequent desiccations are under a vacuum (-15

inHg) at 40ºC using a dry air bleed for 15 hours. A minimum of two

desiccations is required. All assemblies must have two consecutive

weights that are ±10 µg of each other.

- Change desiccant well before it is depleted (e.g., completely

changes color — blue desiccant turns pink). Depending on the local

relative humidity, this might be required several times a week or only

weekly. A filter is used to clean air metered into the vacuum oven when

releasing the vacuum. Change this filter as needed or annually. Release

the vacuum to the oven in a controlled and gradual manner.

- The pre-weighed assemblies are returned to the plastic sleeves with

blue filter spacers separating each assembly and shipped to MSA, Inc.

MSA places each PVC filter assembly in a polystyrene cassette. Each

cassette is sealed with shrink-wrap tape and flow tested. The cassettes

are then returned to the SLTC. Six cassettes are selected at random from

the lot of returned cassettes to be analyzed. After going through the

desiccation procedure, the difference in pre-weights and post-weights is

checked for outliers.

- Use the following protocol when receiving and logging in gravimetric

filter cassette samples. Use the exclusive bar code number affixed to

the filter cassette as the sample submission number. Replace another

sample submission number with the bar code number by lining it out and

initialing it. Record the changes on the OSHA 91A and include a note on

the OSHA 91B analysis report form. Use the following statement in the

note. "When requesting gravimetric analysis, please

use the affixed filter bar code number as the sample submission

number." If the bar code number does not appear on the OSHA 91A,

include in a note that "xxx" submission number corresponds to "yyy" bar

code. The set of laboratory numbers is attached to the sample cassette

for gravimetric analysis. Stamp the numbers on the OSHA 91A as the

samples are originally logged in. After the gravimetric analysis has

been completed, return the filters in the labeled petri dishes to the

proper drawer in the sample room for the additional analysis.

- After verifying and recording the condition of seals and number

agreement, remove filters from their cassettes and place on a

75-position weighing rack. Desiccate all filters (except oil mist,

CrO3 or samples with the potential to lose

volatile organic compounds) in a vacuum oven before pre- and post-

weighing. The initial desiccation is under a vacuum (-15 inHg) at 40ºC

using a dry air bleed for a total of 36 hours. Subsequent desiccations

are under a vacuum (-15 inHg) at 40ºC using a dry air bleed for 15

hours. A minimum of two desiccations is required. Change desiccant well

before it is depleted (e.g., completely changes color — blue desiccant

turns pink). Depending on the local relative humidity, this might be

required several times a week or only weekly. A filter is used to clean

air metered into the vacuum oven when releasing the vacuum. Change this

filter as needed or annually. Release the vacuum to the oven in a

controlled and gradual manner.

- Use an electronic balance capable of weighing to the nearest 0.001

mg. Record the test weights, temperature and humidity in the appropriate

notebook daily before using the balance to weigh filters. After weighing

the test weights, press SELECT 1 twice on the

robot’s balance. The balance is automatically zeroed prior to each

weighing. The balance should be checked by a qualified service

technician every twelve months or when

performance is not acceptable.

- Check the calibration of the balance annually with National

Institute of Standard and Technology Class S-1.1, ASTM Class 1 weights

or equivalent. Use one of the NIST-traceable weights stationed at the

balance. Record its weight into a logbook. One or more other weights —

1- to 1000-mg weights, which are also NIST-traceable — are used to check

the balance and the measured values are documented in the annual balance

audit.

- Weigh the filters using the protocols described in Appendix C.

Equilibrate filters in the environmental controlled room for six hours

prior to each weighing. Use extreme care to

avoid spilling loose dust from the cassette assembly.

- Weigh all filters at least

twice.

- Differences greater than ±10 µg in the two weights require a third

desiccation. If the filter has gained significant weight (e.g.,

>0.2 mg), it must be reweighed until the weights agree within five

percent of the total weight.

- A weight of <66 µg can be reported as "None

Detected, Reporting Limit = 66 micrograms."

- Analyze (weigh) a set of quality control samples with each

analytical set. Quality control samples should be treated in the exact

same manner as the compliance samples. Report and obtain quality control

results. Acceptable QC results must be within the control limits

established before the compliance samples can be reported. Complete a QC

Corrective Action Sheet for any outliers and take appropriate steps to

remedy the problem.

- A detailed description of how to perform the calculations using

the GRAV (Excel) software is given in Appendix

C. Calculations are based on taking the difference between a pre- and

post- weights in milligrams. Subtract a positive weight for the blank

from the net weight. Then divide the results by an air volume in cubic

meters to obtain a particulate concentration in air. DO

NOT add negative weights of the blank to the gravimetric weight.

These calculation conventions are included in the GRAV program.

- Report the results of the gravimetric analysis using the following

IMIS (analyte) codes. Also report any detected blank values. Additional

codes can be found in Appendix A. Report gravimetric results using the

conventions below and with these two IMIS codes:

G302 Sample Weight and blanks reported in mg (Y)

G301

Gravimetric Analysis reported in mg/m³ (M) Report additional

results based on the gravimetric determination using the appropriate

IMIS codes listed and report in mg/m³ (M):

| IMIS |

Analyte |

P104 |

Portland Cement |

| 9130 |

Particles Not

Otherwise Regulated (Respirable Fraction <1% Silica) |

W103 |

Wood Dust (General) |

|

9210 |

Hardwood Dust |

| 9135 |

Particles Not

Otherwise Regulated (Total Dust) |

9211 |

Softwood Dust |

|

C120 |

C120 Coal Dust (>5% Silica)

|

| 5010 |

Oil Mist |

9040 |

9040 Coal Dust (<5%

Silica) |

| 1300 |

Glass Fibrous or Dust |

A100 |

Aluminum

Dust |

Report additional

results based on the determination using other analytical techniques

(e.g., XRD, UV-Vis spectrophotometer, AAS). The IMIS codes listed are

for the more frequently requested additional analysis:

| IMIS |

Analyte |

S103 |

Nonrespirable Quartz |

| 9010 |

Respirable Quartz |

Z102 |

Zinc Oxide |

Care should be taken to report appropriate IMIS codes based

on whether the sample is respirable or nonrespirable. Size determines

respirable vs. nonrespirable particles. Respirable dust particles are

those that are small enough to enter the gas exchange area of the human

lung. For OSHA compliance purposes, these respirable particles are

collected using a 10-mm nylon cyclone where the mean size collected is

approximately 3.5 µm. For practical purposes in reporting gravimetric

results, when the sample has been collected using a cyclone at a

sampling rate of 1.7 L/min, the sample is respirable. Respirable PEL

standards often include a limitation that the dust does not contain

silica in certain percentage. Consult with your team leader as whether

to report this respirable PEL without a silica analysis. Below are

current conventions for reporting gravimetric samples using the LISA

database. These instructions were drafted to help acting team leader’s

understand the appropriate reporting conventions. Our new Oracle

database (LISA) should fine-tuned in the future to eliminate many of the

current shortcomings.

ALL GRAVIMETRIC SAMPLES REQUIRING

SUBSEQUENT CRYSTALLINE SILICA ANALYSIS

- All samples should be Ok'd, Dated and Released when the

gravimetric analysis is reviewed. The samples should be released in

the LISA database. The samples and paperwork should be transferred for

crystalline silica analysis immediately after the completion of the

supervisor review.

- The gravimetric samples associated with crystalline silica samples

should be faxed when the crystalline silica samples are released.

ALL OTHER GRAVIMETRIC SAMPLES

- All other samples should be Ok'd, Dated and Released when the

gravimetric analysis is reviewed.

- If additional analyses are requested (i.e., ICP, AAS), please make

sure that a note is added stating that "The samples

have been resubmitted for ‘X’ analysis. Results will be reported

separately."

- If the gravimetric results yield a result less than the PEL for

the additional analysis requested, report the additional analysis at

the same time the gravimetric samples are released.

- These reports should be completed by the analyst who performed the

gravimetric analysis. Each IMIS analyte must be reported using the

gravimetric results and a "<" symbol. A note should

be included on the FM91B stating that: "The

gravimetric analysis yielded an air concentration that was less than

the PEL. The samples will not be analyzed unless special circumstances

exist and the CSHO calls the SLTC."

- If the additional analyte was for mist and a bulk was submitted,

it should be also reported at this time with the following note:

"The gravimetric analysis for the air samples

yielded an air concentration that was less than the PEL. The bulk

sample will not be analyzed."

- If it appears that the CSHO only used the preweighed filters

because they were convenient, and a weight was not required, please

include a note with the gravimetric analysis that "Preweighed filter should only be used when a gravimetric

analysis is required."

- Confidence limits for the gravimetric analysis are defined by the

reporting of a sampling and analytical error (SAE). The sampling or pump

error is assumed to be ±5% and the analytical error is derived by

analyzing single blind Quality Control samples. A group of 100 data

points is necessary to establish the analytical error. The current SAE

for gravimetric analysis is 0.083 (as of 3/24/03) and covers the range

of 1.0 – 5.0 mg. This gravimetric SAE will be reported for respirable

and nonrespirable PNOR (IMIS 9130 and 9135) and other results based

solely on a gravimetric determination. The quartz results (IMIS 9010)

have a separate SAE, and this number should be referenced for that

analysis.

Appendix A

A Description of the Automatic Weighing

Field Program |

The

SLTC is providing preweighed filters for gravimetric analysis. These

filters should reduce sample preparation time by CSHOs in the field

because the filters are weighed at SLTC and shipped to the field assembled

and ready for use in inspections. The filters will then

be returned to SLTC for gravimetric analysis. Because these filter

cassettes are somewhat different from those currently used, the SLTC has

prepared these instructions.

The filter media is a 37-mm diameter,

low-ash polyvinyl chloride. These filters should be used for silica

(quartz) analysis, aluminum and any other appropriate substance having a

high PEL or requiring gravimetric analysis. The filters may be used

without the cyclone attached for total dust analyses. Please indicate on the 91A form all analytes of interest.

If gravimetric analysis gives a result less than the PEL for the

requested substance(s), no further analysis will be provided unless

specifically requested. (The unassembled filters cost

more than five dollars, so they should only be used for

samples requiring crystalline silica gravimetric analysis or gravimetric

analysis for substances having high PELs which may require no

further analysis based on total weight.) Attached is a partial

listing of substances that can be submitted to the SLTC on the pre weighed

cassettes.

These filters are shipped pre weighed and assembled in

the cassettes. They are available directly from the SLTC. They may also be

ordered through the Cincinnati Technical Center (CTC) "Expendables

Supplies" menu in the "OSHA Property Management Inventory System (OPMIS)."

(Listed as Cassette, Aerosol, 37MM, Preassembled, **Preweighed at SLTC**,

#FES0000161). The SLTC initially planned to distribute a supply of filters

to each area office. The demand for pre weighed filters has overwhelmed

our capability to send the initial supply of preweighed filters every

office and replenish them automatically. Currently the SLTC is

distributing preweighed filters to the area offices by request only. Any

area office that has not received an initial supply of the filters should

contact the SLTC or CTC. Preweighed filter supplies will be replenished

upon request.

Be sure to follow all appropriate protocols for

calibration, sampling and submission of samples. A blank should be

included with every set of samples. Due to the smaller size of the

sampler, check frequently to prevent filter overloading. This can be

accomplished by looking into the inlet sampling port of the cassette or by

visual observation of the airborne dust concentration around the

worker.

The SLTC is now shipping a modified version of the

pre-weighed cassettes. Externally these cassettes are identical to those

previously shipped. The only difference is that new cassettes have a

stainless steel filter support instead of the Tyvek backup pad on the

older style. The stainless steel support seems to be less affected by

humidity (providing a more stable blank weight) than the old pad. Earlier

versions of the cassette may have a numbered sticker on the outlet side of

the cassette, it can be ignored.

It is not necessary to discard the

older style filters. Both styles may even be used in a single inspection.

However, it is very important that the blanks submitted

with a set of samples have the same backup pad as the samples.

Therefore if both styles of filters are used in one inspection, submit

blanks of each style. This will enable the SLTC to perform the correct

blank subtraction for the sampled filters.

The inlet side of the

cassette is marked on the polystyrene cassette. This is the side of the

filter cassette with the metallic antistatic shield. The Tyvek backup pad

or the stainless steel support is visible from the outlet side of the

assembly. Each of the filter assemblies is bar coded for weighing

purposes. To aid in the tracking of the filters, please

use the bar code number for the sample submission number when filling out

OSHA Form 91A.

|

|

| Inlet

Outlet |

New Stainless support

(drawing) |

These filters

were created for use in Mine Safety and Health Administration inspections

by MSA, Inc. They are therefore more readily adaptable for use in the MSA

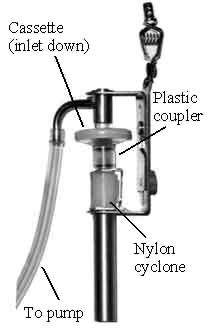

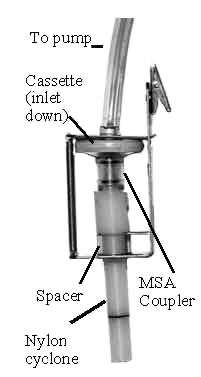

style cyclone assembly. However, the standard MSA coupler (used with a

standard 2- or 3-piece cassette) will not fit these cassettes. They need a

coupler available from MSA (part #457391, price $7.60). This new coupler

is plastic instead of stainless steel. These couplers are also available

through the CTC OPMIS.

|

|

| MSA cyclone holder with

cassette |

Bendix holder

with cassette |

If you have

any further questions about the filters or the autoweighing program,

please contact Fred Cox (801-524-7932) or Steven Edwards

(801-524-7952).

Table

1

PARTIAL LIST OF SUBSTANCES FOR AUTOWEIGHING

SUBMISSION

|

| Analyte |

IMIS |

mg/m³ |

-Alumina -Alumina |

|

|

| Total dust |

0160 |

15 |

| Aluminum Metal (as

AI) |

|

|

| Total Dust |

A100 |

15 |

| Respirable fraction |

A110 |

5 |

| Ammonium

Sulfamate |

|

|

| Total dust |

0185 |

15 |

| Respirable fraction |

A111 |

5 |

| Barium

Sulfate |

B101 |

15 |

| Total dust |

B104 |

5 |

| Bismuth Telluride,

undoped |

|

|

| Total dust |

0370 |

15 |

| Respirable Fraction |

B110 |

5 |

| Boron Oxide |

|

|

| Total dust |

0380 |

15 |

| Calcium

Carbonate |

|

|

| Total dust |

0505 |

5 |

| Respirable fraction |

C130 |

5 |

| Calcium

Hydroxide |

|

|

| Total dust |

|

15 |

| Respirable fraction |

|

5 |

| Calcium Oxide |

0520 |

5 |

| Calcium

Silicate |

|

|

| Total dust |

C112 |

15 |

| Respirable fraction |

C122 |

5 |

| Calcium

Sulfate |

|

|

| Total dust |

C104 |

15 |

| Respirable fraction |

C123 |

5 |

| Carbon Black |

0527 |

3.5 |

| Cellulose |

|

|

| Total dust |

0575 |

15 |

| Respirable fraction |

C124 |

5 |

| Coal dust (<5%

Sio2) |

|

|

| Respirable fraction |

9040 |

|

| Coal dust (>5%

SiO2) |

|

|

| Respirable fraction |

C120 |

|

| Cotton dust

(The SLTC will supply special preweighed cotton

dust filters and cassettes on request.) |

| Dicyclopentadienyl

Iron |

|

|

| Total dust |

0904 |

15 |

| Respirable fraction |

D100 |

5 |

| Emery |

|

|

| Total dust |

1016 |

15 |

| Respirable fraction |

E102 |

5 |

| Grain dust |

|

|

| (oat, wheat, barley) |

G109 |

10 |

| Glycerin

(mist) |

|

|

| Total dust |

1363 |

15 |

| Respirable fraction |

G115 |

5 |

| Graphite,

synthetic |

|

|

| Total dust |

1366 |

15 |

| Respirable fraction |

G100 |

5 |

| Gypsum |

|

|

| Total dust |

1367 |

15 |

| Respirable fraction |

G101 |

5 |

| Kaolin |

|

|

| Total dust |

1568 |

15 |

| Respirable fraction |

K100 |

5 |

| Limestone |

|

|

| Total dust |

1593 |

15 |

| Respirable fraction |

L100 |

5 |

| Magnesite |

|

|

| Total dust |

M113 |

15 |

| Respirable fraction |

1615 |

5 |

| Magnesium Oxide

fume |

|

|

| Total particulate |

1610 |

15 |

| Marble |

|

|

| Total dust |

1626 |

15 |

| Respirable fraction |

M114 |

5 |

| Oil

Mist(Mineral) |

5010 |

5 |

| Particulates not otherwise

regulated (PNOR) |

| Total dust |

9135 |

15 |

| Respirable fraction |

9130 |

5 |

| Pentaerythritol |

|

|

| Total dust |

1987 |

15 |

| Respirable fraction |

P157 |

5 |

| Perlite |

|

|

| Total dust |

2035 |

15 |

| Respirable fraction |

P101 |

5 |

| Plaster of

Paris |

|

|

| Total dust |

2127 |

15 |

| Respirable fraction |

P102 |

5 |

| Portland

cement |

|

|

| Total dust |

0557 |

15 |

| Respirable fraction |

P104 |

5 |

| Rouge |

|

|

| Total dust |

2229 |

15 |

| Respirable fraction |

R102 |

5 |

| Silica, amorphous,

precipitated and gel |

9050 |

|

diacotomaceous earth, containing

<1%

crystalline silica |

S112 |

|

| Silica,

crystalline |

|

|

| Cristobalite, |

|

|

| Respirable dust |

9015 |

|

| Quartz |

|

|

| Respirable dust |

9010 |

|

| Tripoli, (as quartz) |

|

|

| Respirable dust |

S114 |

|

| Tridymite, |

|

|

| Respirable dust |

9017 |

|

| Silica, fused |

|

|

| Respirable dust |

9013 |

|

| Silicates (<1%

crystalline silica) |

|

|

| Mica, |

|

|

| Respirable dust |

9075 |

|

| Soapstone, |

|

|

| Total dust |

9025 |

|

| Respirable dust |

S121 |

|

| Silicon |

|

|

| Total dust |

2235 |

15 |

| Talc (containing

no asbestos) |

|

|

| Respirable dust |

9030 |

|

Appendix B

A description

of the robot and software routines for Automated Gravimetric

Analysis of samples. |

The

robotic systems used for the automated weighing of filters was obtained

from Zymark Corporation, Hopkinton, MA. It consists of eight major

components:

1) Zymark Zymate XP robot to manipulate the

filters

2) turntable for storing up to 600 filters

3) bar

code reader and spinner

4) Mettler MX-5 balance or equivalent,

capable of weighing to 1 µg

5) Zymark System V

controller

6) printer

7) drying ovens

8) Microsoft

Windows-based computer for data viewing, storage and networking

The Zymark System V controller maintains all the software for

the robot operation and gives commands to the other components of the

robotic system as needed for the efficient gravimetric analysis of the

filters. It also tells the robot where the various components are aligned

and allows for periodic adjustment of the components as needed. The PC is

used for input and output from the System V controller. The controller

appears as a window in the Windows operating screens titled "System V

Terminal." This window may be opened by double clicking the icon "System V

Terminal" in the "Zymate Utilities" program group.

Old Robot Instructions

The commands for the

gravimetric analysis are stored in a dictionary in the System V controller and also on

the hard drive of the computer. The dictionary used by this system is

USD-1.

The two programs most often used from the dictionary

are LOAD.TRAYS and WEIGH. To run a program, enter

the name of the program at the Z> prompt in the System V Terminal

window.

The LOAD.TRAYS

(also accessible as LOAD.RACKS) positions the turntable for easy

placement of a filter rack on the turntable. When it is run, it prompts

for the desired turntable rack position. Upon entry of a rack position,

the turntable moves until the requested position is closest to the edge of

the table. CAUTION: Make sure the space around the

turntable is clear before entering a position number to avoid possible

harm or damage to equipment. When loading a rack on the turntable,

make sure the bracket on the rack fits securely over the brace and the

rack is sitting all the way down on the turntable. The program will then

prompt for additional positions to be loaded. Enter N to exit the program and

return to the Z>

prompt.

The WEIGH

( or OSHA.FILTER.WEIGHING) program is used to analyze

a batch of filters. When WEIGH is entered at the Z> prompt, the program initially asks if the

previous data was saved. Enter Y. The program will then initialize the robotic

system. This procedure takes a few minutes. After the initialization is

complete, the program will prompt: What is the starting TURNTABLE rack number of this batch of

filters? (1–8). Enter the turntable

rack position. NOTE: this is position of the rack on the

turntable, not the number printed on top of the

rack! The program will then prompt: What is the starting column number of this batch of filters

(1–5)? There are five columns on each rack (numbered 1–5,

from left to right.) A batch may start in the topmost position of any

column. Enter the starting column number. The program will then

prompt: How many samples are in this

batch? Enter the number of samples to be weighed in this

batch. NOTE: A batch may continue into another rack, but may not continue from the rack in turntable position 8

to turntable position 1. The program will then ask for verification of the

information about the batch. At this time a filename is created for data

storage. The filename consists of the current date and time. The format

for the filename is MMMDDHHM.#

where the month (M.M.) is an abbreviation of the current month

and the extension (#) is the number of the batch

entered. (Example: May12112.2 is the second batch input on May 12 between

11:20 and 11:30 A.M.)

The program will then ask if there are

additional batches to be weighed. When all the batches have been entered,

the program will verify that there is a disk in the System V controller.

The program will then prompt: Enter the start delay in hours (0, for an

immediate start). Enter the start delay (the time before the

robot starts weighing the filters). Decimal hours are permitted (e.g.,

1.25). The program will then prompt: Enter robot exercise time in minutes (0 for none, 10

max). Enter the time for the robot to exercise or warm up

(1–3 minutes are recommended). The screen will then show the time

remaining until the weighing will begin.

When the robot begins the

weighing, it first exercises, then it collects the proper "hand" to

manipulate the filters. Before weighing any filter, the controller queries

the balance calibration status. The Mettler MX-5 balance monitors its

calibration and will recalibrate as necessary. If the query shows the

balance needs recalibration, which will take place before the next filter

is processed. Once the balance calibration is stable, the robot takes the

next filter and checks to make sure it has a filter by placing the filter

above a sensor. If it does not sense a filter, it will try again to grab

the filter. The robot will try to grab a filter four times before writing

to the data file the rack position and the message No_Filter. Each time it tries

to grab the filter, it reaches a little farther into the rack.

Once

the robot grabs the filter, it places it in the bar code reader station to

determine the bar code. While in the bar code station, the filter is spun

and the reader makes multiple attempts to read the bar code. In order to

exit this station, the bar code must agree on two successive readings. If

the bar code doesn’t agree after three attempts (meaning six readings),

the controller will store the bar code as NOT_READ and continue.

After reading the

bar code, the robot retrieves the filter and moves it to the balance

station. In the balance station the filter is held over a Staticmaster to

remove the static. The balance is tared and the filter placed on the

balance. The controller then asks the balance for a stable weight. Once

the stable weight is returned, the filter is retrieved from the balance.

(The controller verifies that the filter has been retrieved by querying

the balance.) The filter is then placed back in the turntable and the rack

position, bar code and weight are written into the data file. The robot

then continues until all filters are weighed. Once all filters and all

batches have been weighed, the "hand" is parked, the robot shuts down and

the controller returns a Z> prompt.

New Robot

Instructions

The commands for the gravimetric analysis are

stored in a dictionary

in the System V controller and also on the hard drive of the

computer. The dictionary used by this system is USD-4.

The two

programs most often used from the dictionary are LOAD.TRAYS and WEIGH. To run a program, enter the name of the

program at the Z> prompt in the System V

Terminal window. If the Z> is not visible, flip the toggle switch to

the UP position or toward the turntable. The

toggle switch is on the black box located to the left of the balance

controller. If the robot is active, wait until it is finished before

flipping the switch. It is also possible to run the LOAD.TRAYS program by first

clicking on the ABORT button. After adding or removing the filter racks,

type WEIGH and press

ENTER to continue.

The LOAD.TRAYS (also accessible as LOAD.RACKS) positions the

turntable for easy placement of a filter rack on the turntable. When it is

run, it prompts for the desired turntable rack position. Upon entry of a

rack position, the turntable moves until the requested position is closest

to the edge of the table. CAUTION: Make sure the space

around the turntable is clear before entering a position number to avoid

possible harm or damage to equipment. When loading a rack on the

turntable, make sure the bracket on the rack fits securely over the brace

and the rack is sitting all the way down on the turntable. The program

will then prompt for additional positions to be loaded. Enter N to exit the program and

return to the Z>

prompt.

The WEIGH

( or OSHA.FILTER.WEIGHING) program is used to analyze

a batch of filters. When WEIGH is entered at the Z> prompt, the program initially asks if the

previous data was saved. Enter Y. The program will then initialize the robotic

system. This procedure takes a few minutes. After the initialization is

complete, the program will prompt: What is the starting TURNTABLE rack number of this batch of

filters? (1–8). Enter the turntable rack position. NOTE: this is position of the rack on the turntable, not the number printed on top of the rack! The

program will then prompt: How many

samples are in this batch? Enter the number of samples to be

weighed in this batch. NOTE: A batch may continue into another rack, but

may not continue from the rack in turntable

position 8 to turntable position 1. The program will then ask for

verification of the information about the batch. At this time a filename

is created for data storage. The filename consists of the current date and

time. The format for the filename is MMMDDHHM.# where the month (M.M.) is an abbreviation of

the current month and the extension (#) is the

number of the batch entered. (Example: May12112.2 is the second batch

input on May 12 between 11:20 and 11:30 A.M.)

The program will then

ask if there are additional batches to be weighed. When all the batches

have been entered, flip the toggle switch DOWN or

toward yourself. The robot will move the filters to an available oven. The

filters will be desiccated and returned to their original positions in the

racks of the turntable. An equilibration time of 6 h is pre-programmed

into the robot.

Before weighing any filter, the controller queries

the balance calibration status. The Mettler MX-5 balance monitors its

calibration and will recalibrate as necessary. If the query shows the

balance needs recalibration, which will take place before the next filter

is processed. Once the balance calibration is stable, the robot takes the

next filter and checks to make sure it has a filter by placing the filter

above a sensor. If it does not sense a filter, it will try again to grab

the filter. The robot will try to grab a filter four times before writing

to the data file the rack position and the message No_Filter. Each time it tries

to grab the filter, it reaches a little farther into the rack.

Once

the robot grabs the filter, it places it in the bar code reader station to

determine the bar code. While in the bar code station, the filter is spun

and the reader makes multiple attempts to read the bar code. In order to

exit this station, the bar code must agree on two successive readings. If

the bar code doesn’t agree after three attempts (meaning six readings),

the controller will store the bar code as NOT_READ and continue.

After reading the

bar code, the robot retrieves the filter and moves it to the balance

station. In the balance station the filter is held over a Staticmaster to

remove the static. The balance is tared and the filter placed on the

balance. The controller then asks the balance for a stable weight. Once

the stable weight is returned, the filter is retrieved from the balance.

(The controller verifies that the filter has been retrieved by querying

the balance.) The filter is then placed back in the turntable and the rack

position, bar code and weight are written into the data file. The robot

then continues until all filters are weighed. After the first weighing,

all of the filters are returned to the ovens for another desiccation

period. All of the filters are reweighed after another equilibration

period. After the second weighing, any filter that have a difference of

>10 µg between its two weights is returned to the ovens for a third

desiccation. The filters are weighed after a third equilibration time.

Once all filters and all batches have been weighed, the "arm" is parked,

the robot shuts down and the controller returns a Z> prompt.

If you need to open an oven door

for some reason, click the ABORT button. Type OPEN.FILTER.OVEN.#, where # is the number of

the oven that needs opening. CLOSE.FILTER.OVEN.# will close the oven when you

are done.

Troubleshooting:

The

robot may be stopped at any time by clicking on the Stop button in the System V

Terminal window or by pressing F9 on the keyboard. Note: pressing Shift F9 should stop the

robot immediately. Pressing F9 may allow the robot

to finish the program line that is being processed. Once the robot

has halted, you may be able to continue by clicking the Step button or the Cont button on the screen or

by pressing F9 to step

forward or F10 to

continue the program. Once the program has stopped, clicking on the Abort button or pressing Shift F10 will end the

program.

Sometimes the robot needs to have its data arrays reset to

default values. This is done from the Z> by typing INIT.SYSTEM. This is only done after all

scheduled weighings are finished and the samples are reported.

If

the robot is frozen and not processing samples, power down the entire

system. This may be done by shutting off the UPS under the table for a few

minutes and then turning it on again. When the controller is rebooted, the

dictionary (USD–4) will need to be reloaded from

the disk in the System V controller. To do this, click on Options and Load Dictionary in the System

V Terminal window. Enter the name of the dictionary (USD–4) and click OK. Loading the dictionary will take a few

minutes then the process can be restarted.

Appendix

C

Gravimetric Calculations using GRAV (Excel) Software

|

- Double click on the GRAV icon. The GRAV icon is usually located on your desktop on

computers using WindowsNT with the Excel client program installed. Also,

the GRAV program can be reached with the icon

entitled with one of these terms "AA_Weighing" on some

computers.

- Filter Data. Purpose: Transfers filter weighing

data files from the ALPHA to the NTSERVER to enable

calculations.

- Select Weighing Samples button. From the

Main Menu of the GRAV program select Filter Data from Rack.

- A dialog box will appear titled "Form 1". The default drive that

should appear is entitled \\ROBOT\WEIGHING or

\\USD4\WEIGHING. If not, reselect it by clicking on it from the

list of choices provided and shown by clicking on the down

arrow.

- Select the BIN subdirectory on the

\\ROBOT\WEIGHING or \\USD4\WEIGHING drive, then click on one of your

raw data files (e.g., Apr27135.1). Click OK.

- Select Used from the dialog box. New is for filters that have been preweighed but not

used in the field. Once the data transfer is complete, the Main Menu

will reappear.

- If you have more than one data file, repeat steps a-d.

- From the Main Menu select Sample Range and

then New Sample Range in the Project dialog box,

up to 100 samples. Type in your sample ranges using common conventions

(e.g., R74001–23, R74102, R74111–2, etc.). Enter QC sample ranges with

the prefix of Q (e.g., Q45600–3). After

completing the range enters click OK. Purpose: Identification of sample sets for weighing

calculations.

- Weighing Calculations. Purpose: Calculates the weight of material on the

filter.

- Select (double click) Weighing

Calculations from the Main Menu, then click on

Select.

- The dialog box shown lists the sample number, new weights, and

used weights for one sample in the sets identified. Select the new and

used weights that you want to use in the sample weight calculations.

The program defaults to the lowest weights unless you change them.

Click OK to accept your choices. Select or

confirm a choice on the subsequent samples.

- When you get to the QC’s a second dialog box will appear titled

"Bar." Enter the bar code (e.g., I490) for the

QC sample identified in the Select dialog box, then click OK.

- Generate Report. Purpose: To print a copy of the

new and used weights for each sample and QC

with the designation of the chosen weights.

- After the last sample is displayed in 4c above, click on the Report button. A window opens with a text file that

lists all weights with your selection for each filter chosen in step

4b.

- Edit the document file using hard returns, when necessary, to make

it easier to be read when printed. Change the printer settings in

Notepad to have the left and right margins to be 0.25 inches. Print

the file to a networked printer (e.g., \\NTSERVER\XRAYHP4). Close

Notepad and return to the Select dialog box.

- Sample calculations. Purpose: Calculates the air

concentration for all samples using the sample weight and sample air

volume.

- Click the Excel button in the Select

dialog box.

- Two workbooks will open up in the Excel program. Select the one

titled "MAINMENU.XLS." Click Here to Run the Weighing

Program begins the procedure to perform the calculation. A

third workbook will open up titled "WEIGHT.XLS" and seen as a tab at

the bottom of the screen.

- Make sure air volumes are correct and fill in "AIR" for QC samples

and "ABLNK" for QC blanks. Click Here to Start

will open a workbook that contains all the sample information along

with the individual chosen weights listed and a net weight

calculation.

- Highlight (click and drag the mouse pointer) an individual sample

set including the blank from this workbook’s column A. Select Range, then Click Here for Blank Corrections!

to perform the air concentration calculation on that set.

Repeat for each set of samples.

- To Print and Exit, Click Here! button

gives a printout of the air concentration in milligrams per cubic

meter along with the net weight found on each filter in

milligrams.

- Close Excel.

- After exiting, the Main Menu will reappear. Select Load Resources to Lisa. Purpose:

Transfers the data (both weight and air concentration) to Lisa for

inclusion in the sample results record.

|