|

| Method no.: |

ID-125G |

| |

|

| Control no.: |

T-ID125G-FV-03-0209-M |

| |

|

| Matrix: |

Air, Wipe, or

Bulk |

| |

|

| OSHA Permissible

Exposure Limits: |

Permissible Exposure

Limits (PELs) are listed in Table

1 for elements commonly found in industrial environments.

This method has the capability of sampling and analyzing more

than these elements, the number being limited by instrumental

capability, as well as digestion solubility and

stability. |

| |

|

| Collection

Procedure: |

A calibrated personal

sampling pump is used to draw a known volume of air through a

mixed-cellulose ester membrane filter contained

in a styrene cassette. |

| |

|

| Minimum Recommended

Air Volumes: |

Time Weighted Average

Samples - 480 L

Short-Term Exposure Limit Samples - 30

L*

Ceiling Samples - 30 L |

| |

|

| Recommended Sampling

Rate: |

2 L/min |

| |

|

| Analytical

Procedure: |

Filters are digested

with nitric acid, sulfuric acid and hydrogen peroxide.

Dissolution of the elements is facilitated by addition of

hydrochloric acid. Analysis is performed using Inductively

Coupled Argon Plasma-Atomic Emission Spectroscopy

(ICAP-AES). |

| |

|

| Detection Limits: |

See Table

2 |

| |

|

| Validation Level: |

See Table

3 |

| |

|

| Precision and

Accuracy: |

See Table

3 |

| |

|

| Method

Classification: |

Validated analytical

method |

| |

|

| Chemist: |

Jerry Septon, Ray

Abel, Michael Simmons |

| |

|

| Date (Revised): |

November, 1988

(September, 2002) |

| |

|

| * Take 60-L samples when evaluating STEL

exposures to beryllium. |

| |

|

Commercial manufacturers and

products mentioned in this method are for descriptive use only

and do not constitute endorsements by USDOL-OSHA. Similar

products from other sources can be substituted.

|

| |

|

Division of Physical Measurements and Inorganic

Analyses

OSHA Technical Center

Sandy City,

Utah

|

1. Introduction

1.1 Scope

1.1.1 This method describes the collection and

subsequent analysis of airborne metal and metalloid

particulate by Inductively Coupled Argon Plasma-Atomic

Emission Spectroscopy (ICAP-AES).

1.1.2 This method provides rapid simultaneous

analysis and data reduction for a wide range of elements,

eliminating the necessity of separate analyses by

conventional atomic absorption techniques.

1.1.3

This method was validated for 13 elements (Be, Cd, Co, Cr,

Cu, Fe, Mn, Mo, Ni, Pb, Sb, V, and Zn). Other

elements can be added to or subtracted from the method.

The capability for expanding the analysis to other

elements is mainly dependent on laboratory instrumentation

and element solubility and stability in the acid matrix

used for digestion. 1.2 History

1.2.1.Previous to the introduction of

ICAP-AES, samples containing metallic particulates were

digested in a variety of ways and analyzed by Atomic

Absorption Spectroscopy (AAS) at the OSHA Analytical

Laboratory.

1.2.2 A first generation plasma source

and spectrometer (Jarrell-Ash Model 975 Atomcomp) was then

used by the OSHA Analytical Laboratory. The analytical

procedure for this instrument is described in OSHA Method

No. ID-125 (8.1).

1.2.3 Procurement of new inductively coupled

plasma (ICP) instruments, computers, and software allowed

samples to be determined using later technology. This

technology includes more sophisticated computer systems

for data reduction and instrument control.

1.2.4

When this method was originally written, three different

ICP instruments at the OSHA Salt Lake Technical Center

(OSHA-SLTC) are used to apply this method:

Jobin-Yvon (JY) Model 32 (Instruments SA,

Edison, NJ)

Jarrell-Ash Model 975 Atomcomp* (Thermo

Jarrell-Ash Corp., Franklin, MA)

Applied Research

Lab. (ARL) Model 3560 (ARL, Sunland, CA)

These instruments are further referred to as

ICP1, ICP2, or ICP3, respectively.

The Jarrell-Ash

system was upgraded with a new computer, generator, and

software in 1989.

This method is applicable to any

simultaneous spectrometer. This method was validated using

ICP1 and the data is presented in a backup report (8.2).

An additional evaluation was performed using ICP3 (8.3).

2. Detection Limits and Working Ranges (8.2)

2.1 OSHA Permissible Exposure Limits (PELs) (8.4)

for the elements screened and validated are listed in Table

1. Detection limits and working ranges are in Table

2. All reported detection limits were calculated for

50-mL solution volumes.

2.2 The optimum working

range for each element listed in Table

2 extends several orders of magnitude above each

detection limit. 3. Method Performance (8.2)

3.1 The precision and accuracy data for the 13

validated elements using ICP1 are listed in Table

3. These values are based on six samples at each

concentration level tested. Solutions of the 13 elements

were spiked on mixed-cellulose ester filters. These samples

were then digested and analyzed using procedures mentioned

in this method and in reference 8.2.

3.2 Nine of the thirteen elements reported in Table

3 were spiked at 0.5, 1, and 2 times the PEL, assuming a

120-L air volume. Spikes for manganese were calculated

assuming a 30-L air volume. Approximately 200-L air volumes

were assumed for Pb, Ni, and Sb.

3.3 The analytical

error (AE) at 95% confidence for each element listed in Table

3 was calculated as:

±AE% = 100 × [|Mean Bias| +

2(CV)]

Analytical errors for all elements tested

were within ±25%; the greatest value was ±18.1% for V. This

element was validated near it's detection limit.

4.

Interferences (8.6)

High temperatures present in the plasma (5,000

to 8,000°C) minimize most chemical and matrix interferences.

Interferences do exist, however, and can be categorized as

follows:

4.1 Physical interferences such as nebulization

and transport effects are influences that determine the rate

and particle size in which analytes are delivered to the

plasma. These effects are minimized by matching the acid

concentrations of samples and standards.

4.2

Chemical interferences are characterized by molecular

compound formation, ionization effects, and solute

volatilization effects. These effects are not severe in ICP

analysis and are minimized by matrix matching and careful

selection of operating conditions such as: incident plasma

source power, sample uptake rate and plasma observation

height.

4.3 Spectral interferences include:

- Unresolved overlap of molecular band spectra.

- Overlap of a spectral line from another element.

- Background from continuous or recombination phenomena.

- Background from stray light.

4.4 The first effect (a) can be minimized by a

careful selection of wavelengths for the reported elements.

The other types of spectral interferences (spectral overlap

and elevated background) are minimized by software which

performs interelement corrections. This software assumes a

linear relationship between the analyte and interference

within the working range limits. A spectral interference

correction equation typically used by ICP manufacturers is:

Corrected Concn = Calculated Concn - Ai ×

CPi

where:

| Ai |

is |

Correction factor |

| CPi |

is |

Concentration of the

interfering element |

Samples having analyte concentrations above

the working range limits should be diluted into range;

interelement corrections may not be accurate above the

working range. Experimentally determined interelement

corrections for the validated elements are listed in

reference 8.2.

4.5. If necessary, supplemental background

correction can be performed with additional software

supplied by the instrument manufacturer.

5.

Sampling

5.1 Equipment

5.1.1 Mixed cellulose ester (MCE) filters

(0.8-µm pore size), cellulose backup pads, and cassettes,

37-mm diameter, part no. MAWP 037 AO (Millipore Corp.,

Bedford, MA). Cassettes, filters (MCE) and backup pads of

25-mm diameter can also be used.

5.1.2 Gel bands

(Omega Specialty Instrument Co., Chelmsford, MA) for

sealing cassettes.

5.1.3 Sampling pumps capable of

sampling at 2 L/min.

5.1.4 Assorted flexible

tubing.

5.1.5 Stopwatch and bubble tube or meter

for pump calibration.

5.1.6 Scintillation vials,

20-mL, part no. 74515 or 58515, (Kimble, Div. of

Owens-Illinois Inc., Toledo, OH) with polypropylene or

Teflon cap liners. If possible, submit bulk or wipe

samples in these vials for ICP analysis.

5.1.7

Smear tabs, part no. 225-24 (SKC Inc., Eighty Four, PA),

or Whatman no. 41 or no. 42 filters (Whatman LabSales Inc.

, Hillsboro, OR) for wipe sampling.

5.1.8 Gloves,

disposable (for wipe sampling).

5.1.9 Ghost Wipes,

4" × 4" 1000/cs Wet with DI Water, part no. SC4250

(Environmental Express, Mt. Pleasant, SC) for wipe

sampling. 5.2 Sampling Procedure - Air

Samples

Welding fumes and samples requiring sample weights can be

characterized using this method. Collect samples on

pre-weighed 37-mm polyvinyl chloride (PVC) filters at 2

L/min flow rate. Conduct the welding fume sampling with the

filter cassette located inside the welding helmet (8.6).

If the free-space inside the hood precludes the use of 37-mm

diameter cassettes and filters, 25-mm sampling assemblies

with pre-weighed PVC filters can be used.

Desiccate

and post-weigh each sample and then calculate total welding

fume exposure:

net

weight (µg) - net weight of blank (µg)

air volume (liters) |

=

mg/m3 |

and determine compliance with the 5

mg/m3 TLV for welding fumes. Submit the samples

to the laboratory for welding fume/ICP analysis to further

characterize the samples.

5.2.1 Place a MCE filter and a cellulose

backup pad in each two- or three-piece cassette. Seal each

cassette with a gel band.

5.2.2 Calibrate each

personal sampling pump with a prepared cassette in-line to

approximately 2 L/min flow rate.

5.2.3 Attach

prepared cassettes to calibrated sampling pumps (the

backup pad should face the pump) and place in appropriate

positions on the employee or workplace area. Collect the

samples at about 2 L/min flow rates. Minimum sampling

times recommended are:

Recommended Sampling Times

|

| Time

Weighted Average Samples |

240 min |

| Short-Term Exposure

Limit Samples |

15

min* |

| Ceiling Samples |

15

min |

The analytical sensitivity of a specific

analyte may dictate using a larger sampling sampling time.

| * |

When determining

compliance with the STEL for beryllium, take 30-min

samples. |

| Note: |

If soluble compounds

(i.e. Cr2+, Cr3+, soluble

salts of Al, Fe, Mo, Ni, ZnCl2, etc.) are

suspected to be present in the sampled air, take

separate samples. Request analysis for the specific

compound(s). These samples are analyzed using OSHA

Method No. ID-121

and not by this method. |

5.2.4 If the filter becomes

overloaded while sampling, another filter cassette should

be prepared. Consecutive samples using shorter sampling

periods should be taken if overloading occurs.

5.2.5 Place plastic end caps on each cassette

after sampling.

5.2.6 Attach an OSHA-21 seal

around each cassette in such a way as to secure the end

caps. 5.3 Sampling

Procedure - Wipe Samples

5.3.1 Wear clean, impervious, disposable

gloves when taking wipe samples to prevent sample

contamination. Change gloves between samples to reduce the

possibility of cross contamination.

5.3.2 Moisten

Smear Tabs and Whatman filters with deionized water prior

to use.

5.3.3 If using a Ghost Wipe remove it from

its package and unfold it. Next fold the Ghost Wipe in

half and wipe a 10-cm × 10-cm area by starting at the

outside edge of the surface, applying firm pressure, wipe

the surface and progress towards the center by making

concentric squares of decreasing size. Fold wipe in half,

with contaminant side in, and wipe the surface again by

making concentric squares of decreasing size. Fold the

wipe in half, contaminant side in, and wipe surface a

third time. If using a Smear Tab or Whatman filter, wipe a

10-cm × 10-cm area by starting at the outside edge of the

surface, applying firm pressure, wipe the surface and

progress towards the center by making concentric squares

of decreasing size. If possible wipe the area at least 3

times.

5.3.4 Fold the wipe sample with exposed side

in. 5.3.5 Transfer the wipe sample into a 20-mL

scintillation vial and seal with vinyl or electrical tape.

Securely wrap an OSHA-21 seal length-wise from vial top to

bottom. 5.4 Sampling Procedure - Bulk Samples

In order of laboratory preference, bulk samples may

be one of the following:

- a high-volume filter sample,

- a representative settled dust (i.e. rafter) sample,

- a sample of the bulk material in the workplace.

Transfer the bulk material

into a 20-mL scintillation vial and seal with vinyl or

electrical tape. Securely wrap an OSHA-21 seal length-wise

from vial top to bottom.

5.5.Shipment

When

other compounds or elements are known or suspected to be

present in the sampled air, such information should be

transmitted with the sample(s) to the laboratory.

5.5.1 Submit at least one blank sample with

each set of air or wipe samples. Blank filter samples

should be handled in the same manner as other samples,

except no air is drawn through the blank.

5.5.2

Send the samples to the laboratory with the OSHA 91A

paperwork requesting ICP analysis.

5.5.3 Bulk

samples should be shipped separately from air samples.

They should be accompanied by Material Safety Data Sheets

if available. Check current shipping restrictions and ship

to the laboratory by the appropriate method.

6.

Analysis

6.1 Safety Precautions

6.1.1

Prepare 1:1 H2SO4 in DI

H2O cautiously.

- Use a 1- or 2-L thick-walled, break- and

heat-resistant bottle.

- Wear thick rubber gloves, plastic apron, labcoat,

and face shield.

- Add 500 mL DI H2O to the bottle.

- Place the bottle over the drain in a sink which has

a slot vent to provide ventilation. Begin running cold

tap water over the side of the bottle, being careful not

to get any tap water in the bottle. Let the level of

water rise in the sink to provide cooling of the bottle.

- Carefully and slowly begin adding 500 mL

concentrated H2SO4 to the DI

H2O. Add a small quantity, swirl to mix, and

allow contents to cool. Do NOT

allow boiling of solution within the container.

- After the acid has been added, loosely cap the

bottle and allow it to remain in the sink with the water

running for at least 15 min. Allow the solution to cool

to room temperature.

- A thick-walled beaker, Teflon-coated stirring bar,

electronic stirrer and a ventilation hood can also be

used to prepare 1:1 H2SO4 if

precautions are taken to prevent solution overheating

and splattering.

6.1.2 Digest all samples

within a suitable exhaust hood.

6.1.3 To prevent

splattering, add H2O2 (30%) to

beakers in 2- to 3-drop groups.

6.1.4 Perchloric acid added to organic

substances can produce fires and/or explosions. If

HClO4 solutions darken in color while heating,

immediately remove beakers from the hotplate and carefully

add a small amount of HNO3. Only use

HClO4 in exhaust hoods designed and reserved

for HClO4 use.

6.1.5 Do not directly

view the plasma.

6.1.6 Do not override the rf

generator or torch box safety interlocks.

6.2 Equipment

6.2.1 Inductively coupled argon plasma/atomic

emission direct-reading spectrometer, cooling unit for

torch assembly, computer, and radio-frequency (rf)

generator.

6.2.2 Nebulizer.

6.2.3

Automatic sampler.

6.2.4 Peristaltic pumps

(optional). Use one pump for automatic sampler rinse. Use

the other pump for sample introduction into the nebulizer.

6.2.5 Mass Flow Controller (optional). Use the

controller to regulate nebulizer argon flow and sample

uptake rate.

6.2.6 Borosilicate glass conical

beakers, 125- and 250-mL.

6.2.7 Borosilicate glass

volumetric flasks, 25-, 50-, 100-, 250-mL, and 1- or 2-L.

Use the larger flasks for standard preparation.

6.2.8 Thick walled, 1- or 2-L heat- and

break-resistant bottle.

6.2.9 Mixed cellulose

ester filters (0.45-µm pore size) and a filtering

apparatus. Use this system to remove any insoluble

particulates from sample solutions.

6.2.10 Hot

plate capable of reaching 300°C.

6.2.11 Volumetric

pipets, glass of various sizes.

6.2.12 Analytical

balance (0.01 mg). 6.3 Reagents (reagent grade or better)

6.3.1 Deionized water (DI

H2O).

6.3.2 Concentrated sulfuric

(H2SO4), hydrochloric (HCl), nitric

(HNO3), and perchloric (HClO4)

acids.

6.3.3 Prepare 1:1

H2SO4 (V/V) solutions as described

in Section 6.1.1

6.3.4 Sample dilution solution or reagent blank

(8% HCl/4% H2SO4):

In an

exhaust hood, slowly and carefully add 40 mL concentrated

H2SO4 to approximately 500 mL of DI

H2O contained in a thick-walled, heat- and

break-resistant bottle. Gently stir and allow the solution

to cool to room temperature. Slowly and carefully add 80

mL concentrated HCl, allow to cool, and dilute to 1 L with

DI H2O.

6.3.5 Stock solutions of 1,000

µg/mL for standard preparation of the various elements.

6.3.6 Hydrogen peroxide,

(H2O2), 30%.

| Note: |

Some manufacturers use

organotin compounds to stabilize

H2O2. Since Sn is one of the

elements screened, use H2O2

that does not contain this type of

stabilizer. |

6.3.7 Argon - quality as specified

by the ICP manufacturer. 6.4 Standard Preparation

Prepare

multielement calibration standards (STD) and continuing

calibration verification (CCV) solutions (see Addendum A for

examples of combinations) using 1,000 or 10,000 Fg/mL stock

solutions. An independent calibration verification (ICV)

standard is a mixture of elements whose concentrations are

within their respective analytical linear ranges and is used

to verify the calibration standards. Whenever possible,

prepare the ICV standard from different stock solutions than

those used for calibration standards. The ICV standard

should contain elements and concentrations reflecting what

is expected in the majority of the samples, or problem

elements. The final acid concentration of the STD, CCV and

ICV standards is 8% HCl/4% H2SO4.

These standards should be stable for at least 6 months.

6.5 Sample Preparation

The final acid

concentration for the different sample matrices should be 8%

HCl/4% H2SO4. All of the elements

validated are soluble when using the following acid

digestion procedures. Other elements not included in the

validated element list (Table

3) should be evaluated for solubility and stability

before using these procedures.

| Note: |

Requests for analysis of

compounds which have a PEL that specifically addresses

the soluble fraction (i.e., Fe, Ni, Mo, etc.) are

analyzed using OSHA Method No. ID-121

and not by this method. |

Filters, backup pads, wipes, and

bulks are prepared by the following procedures:

6.5.1

Mixed-cellulose ester (MCE) membrane filters

- If the beakers used for the digestion have not been

cleaned using a appropriate automated system, clean the

insides of the 125-mL conical beakers by refluxing 1:1

HNO3 using a hot plate in a ventilated hood.

Carefully pour the used 1:1 HNO3 into an

appropriate labeled container. Allow beakers to cool,

then rinse several times with DI H2O and

allow to dry. Using forceps, place sample filters in

separate labeled and washed beakers (If the backup pad

appears contaminated, see Section 6.5.2

below). If the cassette or vial contains loose dust,

carefully pour the dust into the beaker. Always rinse

the cassette with DI H2O and pour the water

into the beaker and wipe out the cassette with a

moistened, clean filter and place this filter in the

sample beaker.

- For samples with air volumes >200 L: Add 4 mL of

1:1 H2SO4, followed by 2 mL of

concentrated HNO3 to each beaker containing

the filter sample. For samples with air volumes < or

= 200 L: Add 2 mL of 1:1 H2SO4,

followed by 2 mL of concentrated HNO3.

- To facilitate the digestion, allow the filters to

sit at least an hour in the 1:1

H2SO4. Add several drops of

H2O2 (30%) to each beaker before

placing it on the hotplate.

- Heat the beakers on a hot plate for approximately 10

min. The solutions should turn brown.

- Cautiously add H2O2 in 2- to

3-drop groups until each solution becomes clear,

colorless, or slightly yellow (the color is dependent on

the concentration and type of analyte present).

- Heat several more minutes until dense, white fumes

of SO3 just become evident. Remove the

beakers from the hotplate and allow to cool.

- Slowly and carefully add the following amount of

concentrated HCl

(CAUTION: SPLATTERING MAY OCCUR IF

THE HCl IS ADDED TOO RAPIDLY OR THE

H2SO4 SOLUTION IS STILL

HOT):

| Acid Addition Data |

Acid Volume

|

|

Air Volume

|

| 4 mL |

|

> 200 L |

| 2 mL |

|

< or = 200 L |

|

- Rinse the sides of the beakers with DI

H2O and return the beakers to the hotplate.

Heat the beakers until near boiling to promote

solubilization of all elements present. Remove the

beakers from the hotplate and allow to cool.

- Quantitatively transfer the solutions into

volumetric flasks using DI H2O. For samples

having air volumes > 200 L, dilute to 50 mL; volumes

< or = 200 L, dilute to 25

mL, if the filter contains a lot of material, dilute to

50 mL.

6.5.2 Backup Pads

- If the backup pad has been contaminated during

collection, digest the pad along with the filter. Also,

separately digest and analyze the blank filter with a

clean backup pad.

- Place each contaminated backup pad and corresponding

filter into individual beakers. Allow to sit at least an

hour in the appropriate amount of 1:1

H2SO4 (Section 6.5.1,

Step 2). Add 10 mL of concentrated HNO3 and

proceed as in Section 6.5.1,

Step 3 above.

6.5.3 Wipe or Polyvinyl Chloride (PVC)

Filter Samples

Polyvinyl chloride filters can be used

for sample collection and analysis by ICP. The industrial

hygienist may sample for gravimetric determinations of

total dust or total welding fumes using PVC filters and

also submit these samples for ICP analysis if a sample

weight is required.

- If the beakers used for the digestion have not been

cleaned using a appropriate automated system, reflux 1:1

HNO3 in 250-mL (for wipes) or 125-mL (for PVC

filters) conical beakers, empty and allow to cool. Rinse

the beakers several times with DI H2O and

allow to dry.

- Place each filter or wipe in a separate washed

beaker.

- Add the appropriate amount of 1:1

H2SO4 as listed below:

Acid Addition Data

|

Acid

Volume*

|

|

Sample

Type

|

| 8 mL |

|

Wipe |

| 4 mL |

|

PVC filter

(> 200 L Air Volume) |

| 2 mL |

|

PVC filter

(>< or = 200 L Air Volume) |

| * Concentrated HCl or 1:1

H2SO4

|

- Add 10 mL concentrated HNO3 to each

beaker. Place the beakers on the hotplate.

- Add H2O2 in 2- to 3-drop

groups. PVC filters and wipes require more

H2O2 for digestion than MCE

filters.

- If HClO4 digestion precautions are

followed (Section 6.1.4),

1 to 2 mL of HClO4 can also be used to

complete digestion. The PVC filter will not

completely digest if HClO4 is not added;

therefore, thoroughly rinse the filter residue with DI

H2O during quantitative transfer of the

sample solution.

- Allow digested samples to cool and carefully add the

same volume of concentrated HCl as the 1:1

H2SO4 used in Section 6.5.3,

Step 3. above.

- Rinse the sides of the beaker with DI H2O

and then heat to near boiling.

- After beakers have cooled to room temperature,

dilute digested wipe solutions to 100 mL. Dilute PVC

filter solutions to final volumes as stated in Section

6.5.1,

Step 9.

6.5.4 Ghost Wipes

- If the beakers used for the digestion have not been

cleaned using a appropriate automated system, reflux 1:1

HNO3 in 125-mL conical beakers, empty and

allow to cool. Rinse the beakers several times with

deionized water and allow them to dry.

- Place each Ghost Wipe in a separate washed beaker.

- Add 4 mL of 1:1 H2SO4 to each

beaker. Let sample sit for 5 minutes.

- Add 2 mL of deionized water followed by 2 mL

concentrated HNO3 to each beaker. Let samples

sit for 15 minutes. After 15 minutes, up to 8 mL more of

concentrated HNO3 can be added to facilitate

digestion, especially if samples are heavily loaded.

Place the beakers on the hotplate.

- When solutions turns brown or black cautiously add

H2O2 in 2- to 3-drop groups until

each solution becomes clear, colorless, or slightly

yellow (the color is dependent on the concentration and

type of analyte present). Ghost Wipes may require up to

10 mL H2O2 before solution clears.

- Heat solutions several more minutes until dense,

white fumes of SO3 just become evident.

Remove beakers from hotplate and allow them to cool.

- After samples have cooled carefully add 4 mL of

concentrated HCl to each beaker.

- Rinse the sides of the beaker with deionized water

and then heat again on hot plate until samples are near

boiling.

- After beakers have cooled to room temperature,

dilute digested Ghost Wipes solutions to 50 mL.

6.5.5 Bulks

- Review any available material safety data sheets to

determine safe bulk handling. The safety data may also

offer a clue as to the aliquot amount needed for

adequate detection of the element(s) of interest.

- Measure by volume or weight an appropriate aliquot

of any liquid bulk sample. Weigh the appropriate amount

of any solid bulk sample. Weigh an aliquot of any paint

bulk by placing a small amount on a MCE filter, allow to

air dry then take the dry weight.

| Note: |

Aliquot amounts of

bulks are dependent on the analytical sensitivity,

detection limit, and solubility of the material

used. If uncertain, a 20- to 50-mg aliquot of a

solid material can be taken as a starting point.

Make sure the aliquot taken is representative of the

entire bulk sample. If needed, use a mortar and

pestle to grind any nonhomogeneous particulate bulk

samples in an exhaust hood. |

After measuring,

transfer the aliquot to a previously cleaned or

acid-washed 250-mL conical beaker.

- Add 20 mL of 1:1 H2SO4 and

digest on a hotplate. Hydrogen peroxide (dropwise) and a

few mLs of HNO3 can be carefully added to

break up the matrix.

| Caution: |

Do not add the

HNO3 to wet bulk materials containing

organic solvents. Significant reactions could

occur. |

- Remove the beaker from the hotplate and allow to

cool. Carefully add 20 mL of concentrated HCl and then

heat the solution to near boiling.

- Allow to cool and quantitatively transfer to a

250-mL volumetric flask. Dilute to volume with DI

H2O.

Air, wipe, and bulk samples: If

particulates are present in any of the sample solutions,

filter this solution through a MCE filter (0.45-µm pore

size) and then re-digest the particulate and filter. Save

the filtrates for analysis. 6.6 Instrument Startup and Calibration

Follow the manufacturer's instructions for

instrument start-up and calibration. An example of ICP

operating parameters is shown below. These settings will

vary from instrument to instrument:

| Gas Used |

Argon |

|

Gas

Flow

(Rotameter settings) |

Plasma

Nebulizer

Auxiliary Plasma |

12 - 16

L/min

*

0.14 - 0.18 L/min |

| RF Power |

Incident

Reflected |

1.1 kW

< 5 W |

| Observation

Height |

Plasma |

15 mm above work

coil |

| Integration

Time |

Peak Signal |

3 to 10 s |

| Wash Time |

Automatic

Sampler

Without Automatic Sampler |

60 s

10 s |

| Number Of

Exposures |

Standards &

Samples |

2 to 10 |

| Nebulizer* |

Solution Uptake

Rate

Pressure |

0.8 - 1.6 mL/min

~30

psig |

| Mass Flow

Controller |

Flow Rate Range |

varies* |

| * This flow

will vary depending on the type of nebulizer in

use. |

6.6.1 Profile the

instrument before beginning the calibration and analysis.

Follow the Standard Operating Procedure (SOP) (8.7)

or manufacturer's instructions for computer initialization

and profiling.

6.6.2 Obtain a two-point

calibration curve by nebulizing the working standards into

the plasma and measuring atomic emission intensities. For

most instruments, a first-order linear fit of the data is

computer calculated and slope and intercept coefficients

are obtained. Perform calibrations by following the

instrument manufacturer's guidelines.

6.6.3 See

Addendum A for the proper sequence of standards and

samples during the analysis. 6.7 Analytical Procedure

For more

details regarding analytical procedures, refer to the

instrument manufacturer's software manual(s) or the SOP (8.7).

6.7.1

If necessary, determine detection limits using the

manufacturer's software (if available). These limits

normally do not significantly change during short time

spans. A general rule is to recalculate detection limits

when an integral component (nebulizer, torch, mass flow

controller, etc.) of the ICP has been replaced or

adjusted. A typical calculation of detection limit (DL) is

shown:

| DL =

|

(K ×

SDI × C)

(I - Io) |

×

S |

where:

| S |

is |

Solution volume in

mL |

| K |

is |

Degree of confidence

(sigma value)* |

| SDI |

is |

Standard deviation of

reagent blank intensity (Io.) |

| C |

is |

Concentration of the

calibration standard in µg/mL |

| I |

is |

Total intensity of

standard containing concentration C |

| Io |

is |

Background intensity

(reagent blank) | * In most cases, K=2 or 3 for qualitative

and K=10 for quantitative determinations.

Reporting limits may be equal to or larger than the

calculated detection limits. Reporting limits should be

verified annually for each matrix.

6.7.2 Analysis

using an automatic sampler is described below:

- Fill automatic sample vials to the minimum sample

volume for one analysis and a potential rerun.

- Load the automatic sampler with labeled standard and

sample vials. A multielement working standard should be

analyzed after every 5 to 6 samples. A control standard

should be occasionally analyzed to ensure proper

instrument operation. If an element or elements

contained in the control standard are not within

specification (a general rule is to use a value less

than ±10 to 15% of the known concentration), the analyst

should recalibrate before proceeding with the analysis.

- Aspirate each sample or standard for approximately 1

min prior to initiating the exposure cycle. This ensures

equilibration in the plasma and minimizes carry-over

effects.

- Dilute and reanalyze any samples containing elements

(both screened and validated) exceeding the working

range (Table

2). In particular, notice the reduced upper

limit (8 µg/mL) for lead. Interelement corrections may

not be accurate above the working range. Prepare the

dilutions by pipetting an appropriate aliquot from the

original solution and dilute with 8% HCl/4%

H2SO4.

- Based on the calibration curve initially obtained,

convert the sample intensities to concentrations. Then,

using the air volume, solution volume, dilution factor

and sample weight, calculate the concentration for each

element analyzed as mg/m3 (air samples),

total micrograms (wipes), or percentage of total weight

(bulks) using the equations shown below.

6.8

Calculations

6.8.1 Total amount of

analyte in the sample:

| µg A =

(µg/mL A) × (mL S) × (DF) |

(1) |

where:

| µg A |

is |

Total µg of

analyte in the sample |

| µg/mL A |

is |

Measured

concentration of analyte in sample solution (derived

from calibration curve) |

| mL S |

is |

total volume

of the solution analyzed |

| DF |

is |

amount of

dilution applied to an aliquot of the original

solution (ratio of final volume divided by the

aliquot volume) | 6.8.2 The blank value, if any, is subtracted

from each sample:

where:

| µgc A |

is |

µg of analyte, blank

corrected |

| µgb A |

is |

µg of analyte in

blank |

6.8.3 For air samples, the concentration of

analyte in the sample is expressed in mg analyte per cubic

meter for each element or compound analyzed:

| mg/m3 = |

(µgc A) × (GF)

air volume (L) | |

(3) |

where:

GF is Gravimetric Factor

For those elements having a

PEL listed as an oxide, the gravimetric factors for the

validated elements are:

1.4298 for

Fe2O3

1.2447 for

ZnO 1.7852 for

V2O5

6.8.4 Convert bulk

sample analytes to % composition using:

| %(w/w) = |

(µgc A) (100%)

(sample weight) (1,000

µg/mg) | |

(4) |

where:

| µgc A |

is |

analyte amount

(µg) |

| Sample wt |

is |

aliquot (in mg) of bulk

taken in Section 6.5.4 | 7. Reporting Results

7.1 Air sample results are reported as

mg/m3. Results for analytes having a PEL as an

oxide are reported as mg/m3 of the oxide.

7.2 Wipe sample concentrations are calculated and

reported as total micrograms for each element.

7.3

Bulk sample results are calculated and reported as elemental

percent by weight (or volume if liquid aliquots were used).

Due to differences in sample matrices between bulks and

standards, bulk results are approximate for each element

determined. (Elemental values are to be reported for all

bulk analyses, do not use a gravimetric factor.)

7.4

Determinations of the screened elements or compounds are not

routinely reported. Spectral interference corrections for

these analytes are not included and validations have not

been performed. If a sample has a screened analyte over the

PEL, the analyst should contact her/his supervisor.

Additional sampling, or if possible, additional analysis of

the original sample should be performed to quantitate the

potential overexposure. 8. References

8.1 Occupational Safety and Health Administration

Analytical Laboratory: OSHA

Analytical Methods Manual (USDOL/OSHA-SLCAL Method

No. ID-125). Cincinnati, OH: American Conference of

Governmental Industrial Hygienists (Pub. No. ISBN:

0-936712-66-X), 1985.

8.2 Occupational Safety and Health Administration

Technical Center: ICP Backup Data

Report (ID-125G) by J.C. Septon. Salt Lake City, UT.

Revised 1991.

8.3 Occupational Safety and Health Administration

Technical Center: ICP Backup Data

Report (ARL 3560) by J.C. Septon. Salt Lake City, UT.

In progress.

8.4 "Toxic and

Hazardous Substances," Code of Federal

Regulations Title 29, Pt. 1910.1000, Subpart Z. 1987.

pp 676-682.

8.5 National Institute for Occupational Safety and

Health: NIOSH Manual of Analytical

Methods, 2nd ed., Vol. 7 (DHEW/NIOSH Pub. No.

82-100). Cincinnati, OH, 1981. Method No. 351.

8.6 United States Department

of Labor, OSHA: "Memorandum, Sampling for Welding

Fumes" by Patricia Clark, Director Designate, Directorate of

Compliance Programs. United States Department of Labor,

OSHA, Washington, DC, February 14, 1989. [Memo].

8.7 Occupational Safety and

Health Administration Analytical Laboratory: ICP Standard Operating Procedure by J.C.

Septon. Salt Lake City, UT. 1988 (unpublished).

Table 1

Air

Contaminants - OSHA Permissible Exposure Limits* |

|

| Element |

Substance

Exposed to |

PEL

(mg/m3)

|

|

|

|

TWA |

CEILING |

|

|

|

|

| Ag** |

Metal and

soluble compounds

(as Ag) |

0.01 |

|

|

|

| As** |

Inorganic

compounds (as As) |

See

29 CFR 1910.1018 for applications |

| Be# |

Beryllium and

compounds

(as Be) |

0.002 |

0.005## |

|

|

|

| Ca** |

Calcium

oxide |

5 |

|

|

|

| Cd |

Fume

Dust

(See 29 CFR 1910.1027) |

0.1

0.2 |

0.3

0.6 |

|

|

|

| Co |

Metal dust and

fume (as Co) |

0.1 |

|

|

|

| Cr |

Cr metal (as

Cr) |

1 |

|

|

|

| Cu |

Fumes (as

Cu)

Dusts and mists (as Cu) |

0.1

1 |

|

|

|

| Fe |

Dicyclopentadienyl iron Total dust

Iron

oxide fume (as Fe2O3) |

15

10 |

|

|

|

| Fe,V |

Ferrovanadium

dust |

1 |

|

|

|

|

| Mg** |

Magnesium oxide

fume Total particulate |

15 |

|

|

|

| Mn |

Mn compounds

(as Mn)

Mn fume (as Mn) |

|

5

5 |

|

|

|

| Mo |

Insoluble

compounds (as Mo) Total dust |

15 |

|

|

|

| Ni |

Metal and

insoluble

compounds (as Ni) |

1

1 |

|

|

|

| Pb |

Inorganic (see 29 CFR 1910.1025) |

| Sb |

Sb and

compounds (as Sb) |

0.5 |

|

|

|

| Se** |

Se and

compounds (as Se) |

0.2 |

|

|

|

| Sn** |

Inorganic

compounds except oxides (as Sn) |

2 |

|

|

| Te** |

Te and

compounds (as Te) |

0.1 |

|

|

|

| Zn |

Zinc oxide

fume

Zinc oxide Total dust

Zinc stearate Total

dust |

5

15

15 |

|

|

|

|

|

| * |

From reference

8.4 |

| ** |

Elements screened -

PELs are listed for information only, because

the screened elements are not digested or

analyzed using optimum conditions. |

| # |

Beryllium also has

a Peak PEL of 0.025 µg/m³. |

| ## |

Both the Ceiling

Limit and the STEL for beryllium are for a

maximum 30-min

duration. | |

|

| Note: |

Compounds having

total and respirable dust PELs of 15 and 5 mg/m³

respectively, are normally analyzed

gravimetrically. Elements contained in these

dust samples can be identified by this or other

methods, if

necessary. | |

Table 2

Detection Limits* and

Upper Limits |

Analyte

|

Qual. Det.

Limit

(µg)

|

Quan. Det.

Limit

(µg)

|

Upper

Limit

(µg/mL)

|

| Ag** |

1.1 |

3.8 |

** |

| Al** |

6.8 |

23. |

200 |

| As** |

1.7 |

5.7 |

20 |

| Be |

0.013 |

0.043 |

5 |

| Ca** |

0.79 |

2.6 |

20 |

| Cd |

0.14 |

0.47 |

50 |

| Co |

1.2 |

4.0 |

100 |

| Cr |

0.40 |

1.3 |

50 |

| Cu |

0.64 |

2.1 |

50 |

| Fe |

8.9 |

30. |

200 |

| Mg** |

2.1 |

7.1 |

20 |

| Mn |

0.061 |

0.20 |

15 |

| Mo |

0.52 |

1.7 |

100 |

| Pb |

2.1 |

7.0 |

8 |

| Ni |

0.59 |

2.0 |

100 |

| Sb |

4.2 |

14. |

100 |

| Se** |

3.2 |

11. |

20 |

| Si** |

2.4 |

8.1 |

20 |

| Sn** |

3.5 |

12. |

** |

| V |

0.57 |

1.9 |

100 |

| Zn |

0.14 |

0.47 |

50 |

| * |

Calculations are based on

a 50-mL solution volume and equations listed in

Section 6.7.1

Each detection limit is dependent on the spectral

wavelength and order used for analysis. |

| ** |

Screened elements -

Limits are approximate - the digestion and analysis

are not optimized for these

elements. |

Both the detection limits and upper limits

were determined using ICP1 (JY-32 ICP). Performance may vary

from instrument to instrument. Upper limits are the upper

linear range for each element. These were determined using a

linear model (8.2).

Table 3

Precision and Accuracy

Data* for Spiked Samples |

|

Element

|

CV

|

Bias

|

Range

(µg)

|

Analytical

Error (± %)

|

| Be |

0.010 |

0.010 |

0.12-0.48 |

2.9 |

| Cd1 |

0.014 |

-0.005 |

6-24 |

3.2 |

| Co |

0.020 |

-0.040 |

6-24 |

8.1 |

| Cr2 |

0.015 |

-0.074 |

60-240 |

10.3 |

| Cu3 |

0.017 |

0.054 |

60-240 |

8.7 |

| Fe |

0.018 |

-0.012 |

420-1680 |

4.8 |

| Mn |

0.032 |

0.077 |

75-300 |

14.1 |

| Mo4 |

0.047 |

-0.029 |

225-900 |

12.3 |

| Ni |

0.025 |

0.017 |

105-420 |

6.6 |

| Pb |

0.040 |

0.04 |

5-20 |

12.1 |

| Sb |

0.014 |

0.012 |

60-240 |

3.9 |

| V |

0.045 |

0.090 |

3.5-14 |

18.1 |

| Zn |

0.007 |

0.014 |

240-960 |

2.9 |

| * |

Reported values were

obtained from ICP1 (ISA JY-32 ICP). Results may vary

from instrument to

instrument. | The

following exceptions were used when calculating spike

amounts:

| 1 |

PEL for fume (0.1

mg/m3) used |

| 2 |

PEL for insoluble forms

(1 mg/m3) used |

| 3 |

PEL for dust form (1

mg/m3) was used |

| 4 |

5 mg/m3 target

concentration was used. This was performed because a

very large amount of spike would be necessary if the

15 mg/m3 PEL for Mo was used. |

|

| CV |

Coefficient of

Variation |

| Instrument Calibration & Quality Control

Sequence |

QC

Function |

Acronym |

Frequency |

Acceptance

Criteria |

Analytes & Nominal Concentrations

(ppm) |

Initial

Calibration1 |

CB |

At the beginning of each analytical

sequence

and

as

required by failing performance checks |

n/a |

|

| STD-A |

RSD <

2%

(replicate

readings) |

Target analytes reported to

clients:

1 - Be

5 - Cr, Cu, Pb, V

10 -

Cd. Co, Mn, Mo, Ni, Sb, Zn

100 - Fe |

| STD-B |

Anticipated interfering

analytes:

1 - Ag, Pt

10 - Al, As, Ce, Mg,

Nb, Se, Sn, Ti |

Initial

Performance

Checks |

ICV |

Immediately

following the initial

calibration |

90-110%

Recovery |

0.5 - Be

2.5 - Cr,

Cu, Pb, V

5 - Cd, Co, Mn, Mo, Ni, Sb, Zn

50 -

Fe |

| CCV |

Immediately following each calibration event in the

analytical sequence

(IB must follow ICS) |

0.5 - Be

2.5 - Cr,

Cu, Pb, V

5 - Cd, Co, Mn, Mo, Ni, Sb, Zn

50 -

Fe |

| RLV |

75-125%

Recovery |

0.002 - Be

0.01 -

Cd

0.03 - V

0.05 - Co, Cu, Mn

0.1 - Pb

0.2

- Cr

0.5 - Fe, Mo, Ni, Sb, Zn |

| ICS |

85-115%

Recovery

(Target

Analytes

Only) |

0.2 - Be, Cd

1 - Pb,

V, Ag

5 - Co, Cr, Co, Mn, Mo, Ni, Sb, Zn, As, Se,

Sn

10 - Ce, Nb, Pt

200 - Fe, Al, Mg, Ti |

| IB |

|X| <

Reporting Limit

(Target

Analytes Only) |

|

Continuing

Performance

Checks |

CCV |

Every 10

field

samples |

90-110%

Recovery |

0.5 -

Be

2.5 - Cr, Cu, Pb, V

5 - Cd, Co, Mn, Mo, Ni,

Sb, Zn

50 - Fe |

| RLV |

75-125%

Recovery |

0.002 -

Be

0.01 - Cd

0.03 - V

0.05 - Co, Cu,

Mn

0.1 - Pb

0.2 - Cr

0.5 - Fe, Mo, Ni, Sb,

Zn |

| IB |

|X| <

Reporting Limit

(Target

Analytes Only) |

|

Sequence

Termination

Performance

Checks |

CCV |

At the end

of

the

analytical

sequence |

90-110%

Recovery |

0.5 -

Be

2.5 - Cr, Cu, Pb, V

5 - Cd, Co, Mn, Mo, Ni,

Sb, Zn

50 - Fe |

| RLV |

75-125%

Recovery |

0.002 -

Be

0.01 - Cd

0.03 - V

0.05 - Co, Cu,

Mn

0.1 - Pb

0.2 - Cr

0.5 - Fe, Mo, Ni, Sb,

Zn |

| IB |

|X| <

Reporting Limit

(Target

Analytes Only) |

|

| Term: |

STD |

Calibration

Standard(s) |

|

CB |

Calibration

Blank |

|

ICV |

Independent

Calibration Verification (alternate source reference

material) |

|

CCV |

Continuing Calibration

Verification |

|

IB |

Instrument Blank (part

of continuing calibration verification) |

|

RVL |

Reporting Limit

Verification |

|

ICS |

Interference Check

Sample |

|

Target

Analyte: any analyte that is reported to clients in

the final report of

results | 1The linear calibration range for

target analytes may be established/verified for each

analytical sequence by analyzing a high level calibration

verification standard at the end of the analytical sequence.

In order to report sample results that are measured at

levels between this high standard and the initial

calibration standard, the high standard must exhibit a

recovery between 90 and 110%.

Addendum B

Ghost Wipe Backup Data

|

- Backup Data

General background

information about the determination of detection limits

and reproducibility of the overall procedure is found in

the "Evaluation Guidelines for Surface Sampling

Methods"1.

The Guidelines define analytical parameters, specific

laboratory tests, statistical calculations and acceptance

criteria.

Sample preparation of Ghost Wipes was

performed as described in Section 6.5.4 of OSHA Method

ID-125G. Instrument analytical conditions used are

described in Section 1.9 of this document. Lot

number

of Ghost Wipes used was 9901, manufactured on May 20,

1999.

1.1 Detection Limit of the overall procedure

(DLOP) and reliable quantitation limit (RQL).

The

DLOP is measured as mass per sample. Seven Ghost wipes

were spiked with descending increments of analyte. These

spiked Ghost Wipes, and a sample blank, were analyzed

and the data obtained used to calculate the required

parameters (standards error of estimate and the slope)

for the calculation of the DLOP.

The RQL is

considered the lower limit for precise quantitative

measurements. It is determined from the regression line

parameters obtained for the calculation of the DLOP,

providing 75% to 125% of the analyte is

recovered.

The analyte target, calculated

DLOPs, and RQLs for the 13 validated analytes are shown

below:

Table 1.1.1

Target Concentrations,

DLOPs, and RQLs |

|

analyte

and

wavelength |

target

concn

(µg) |

DLOP

(µg) in 50 mL |

RQL

(µg) in 50 mL |

recovery

at RQL*

(%) |

|

| BE

313.107 |

4 |

0.0052 |

0.017 |

112.8 |

| Cd

214.440 |

10 |

0.053 |

0.18 |

94.6 |

| Co

228.616 |

200 |

0.32 |

1.1 |

101.2 |

| Cr

267.716 |

1000 |

1.0 |

3.4 |

101.2 |

| Cu

324.752 |

200 |

0.45 |

1.5 |

106.0 |

| Fe

238.204 |

2000 |

1.5 |

5.1 |

105.5 |

| Mn

257.610 |

400 |

0.29 |

0.97 |

101.1 |

| Mo

202.031 |

1000 |

0.8 |

2.7 |

103.8 |

| Ni

232.003 |

1000 |

0.92 |

3.1 |

97.5 |

| Pb

220.353 |

100 |

0.55 |

1.8 |

81.9 |

| Sb

206.836 |

1000 |

1.5 |

5.1 |

105.8 |

| V

292.402 |

56 |

0.08 |

0.29 |

103.1 |

| Zn

213.857 |

800 |

2.2 |

7.3 |

95.4 |

| *Percent

recovery at or near the RQL.

Table 1.1.2

Detection Limit of the

Overall Procedure for Beryllium |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

-7.4 |

| 0.012 |

64.7 |

| 0.025 |

121.9 |

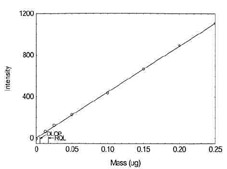

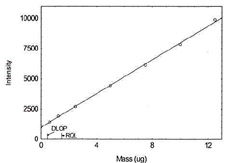

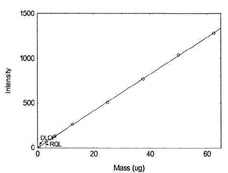

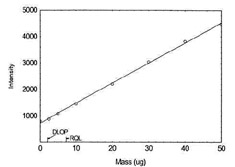

| Figure 1.1.2 Plot of data to

determine DLOP/RQL for Beryllium. (Y=44.36.7X

+2.2) |

| 0.05 |

224.5 |

| 0.1 |

436.1 |

| 0.15 |

666.4 |

| 0.2 |

895.1 |

| 0.25 |

1110.4 |

|

Table 1.1.3

Detection Limit of the

Overall Procedure for Cadmium |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

0.4 |

| 0.031 |

4.5 |

| 0.062 |

4.6 |

| 0.12 |

9 |

| 0.25 |

15.8 |

| 0.38 |

24.6 |

| 0.5 |

32.5 |

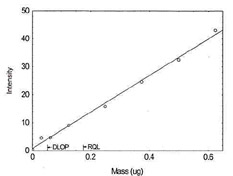

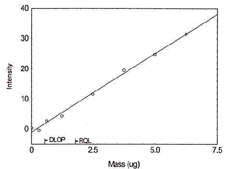

Figure 1.1.3. Plot of data to determine

the DLOP/RQL for Cadmium. (Y=65.2X + 0.7) |

| 0.63 |

43 |

|

Table 1.1.4

Detection Limit of the

Overall Procedure for Cobalt |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

-2.1 |

| 0.62 |

26.7 |

| 1.25 |

52.9 |

| 2.5 |

104.8 |

| 5 |

206.7 |

| 7.5 |

318.5 |

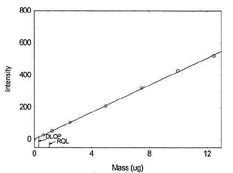

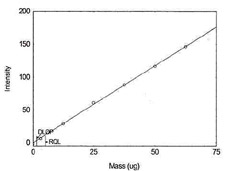

Figure 1.1.4. Plot of data to determine

DLOP/RQL for Cobalt. (Y=42.2X + 0.4) |

| 10 |

428.2 |

| 12.5 |

519.8 |

|

Table 1.1.5

Detection Limit of the

Overall Procedure for Chromium |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

46.3 |

| 3.1 |

673.8 |

| 6.2 |

1332.1 |

| 12.5 |

2749 |

| 25 |

5258 |

| 37.5 |

8015 |

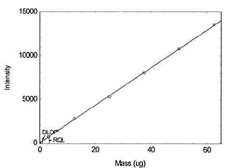

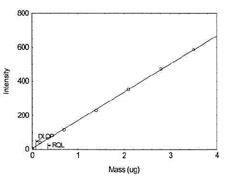

Figure 1.1.5. Plot of data to determine

DLOP/RQL for Chromium. (Y=215.6X - 6.5) |

| 50 |

10769.5 |

| 62.5 |

13546.3 |

|

Table 1.1.6

Detection Limit of the

Overall Procedure for Copper |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

1050.3 |

| 0.62 |

1404 |

| 1.3 |

1904.2 |

| 2.5 |

2687.7 |

| 5 |

4444.8 |

| 7.5 |

6128.2 |

| 10 |

7844.6 |

Figure 1.1.6. Plot of data to determine

DLOP/RQL for Copper. (Y=136.4X + 648.9) |

| 12.5 |

9893.2 |

|

Table 1.1.7

Detection Limit of the

Overall Procedure for Iron |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

699.2 |

| 6.2 |

1546.4 |

| 12.5 |

2371.5 |

| 25 |

4035.6 |

| 50 |

7338.3 |

| 75 |

10830.9 |

| 100 |

14309.3 |

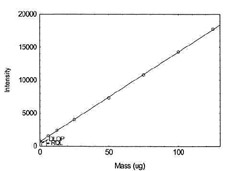

Figure 1.1.7. Plot of data to determine

DLOP/RQL for Iron. (Y= 136.4X + 648.9) |

| 125 |

17759.7 |

|

Table 1.1.8

Detection Limit of the

Overall Procedure for Manganese |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

166.6 |

| 1.2 |

2552.4 |

| 2.5 |

5015.1 |

| 5 |

9899.9 |

| 10 |

19028.4 |

| 15 |

28853.3 |

| 20 |

38573.7 |

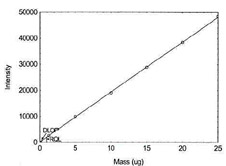

Figure 1.1.8. Plot of data to determine

DLOP/RQL for Manganese. (Y= 1924.2X + 124.5) |

| 25 |

48431.3 |

|

Table 1.1.9

Detection Limit of the

Overall Procedure for Molybdenum |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

-2.7 |

| 3.1 |

32.3 |

| 6.2 |

63.2 |

| 12.5 |

130.3 |

| 25 |

251.6 |

| 37.5 |

388 |

| 50 |

515.2 |

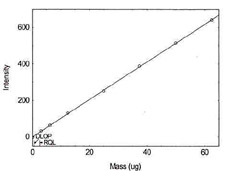

Figure 1.1.9. Plot of data to determine

DLOP/RQL for Molybdenum. (Y= 10.3X - 1.1) |

| 62.5 |

641.4 |

|

Table 1.1.10

Detection Limit of the

Overall Procedure for Nickel |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

0.9 |

| 3.1 |

65.5 |

| 6.2 |

135.7 |

| 12.5 |

265.1 |

| 25 |

508.5 |

| 37.5 |

770.4 |

| 50 |

1040.4 |

Figure 1.1.10. Plot of data to determine

DLOP/RQL for Nickel. (Y= 20.6X + 3.0) |

| 62.5 |

1284 |

|

Table 1.1.11

Detection Limit of the

Overall Procedure for Lead |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

0.3 |

| 0.31 |

-0.4 |

| 0.62 |

2.7 |

| 1.25 |

4.3 |

| 2.5 |

11.6 |

| 3.8 |

19.5 |

| 5 |

24.8 |

Figure 1.1.11. Plot of data to determine

DLOP/RQL for Lead. (Y= 5.2X - 1.0) |

| 3.2 |

31.5 |

|

Table 1.1.12

Detection Limit of the

Overall Procedure for Antimony |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

-1.3 |

| 3.1 |

6 |

| 6.2 |

15.2 |

| 12.5 |

28.8 |

| 25 |

60.8 |

| 37.5 |

88.1 |

| 50 |

116.6 |

Figure 1.1.12. Plot of data to determine

DLOP/RQL for Antimony. (Y= 2.4X - 0.4) |

| 62.5 |

146.3 |

|

Table 1.1.13

Detection Limit of the

Overall Procedure for Vanadium |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

5.7 |

| 0.17 |

39.8 |

| 0.35 |

64.5 |

| 0.7 |

114.6 |

| 1.4 |

230.2 |

| 2.1 |

352.4 |

| 2.8 |

472.4 |

Figure 1.1.13 Plot of data to determine

DLOP/RQL for Vanadium. (Y= 165.9X + 4.6) |

| 3.5 |

586.7 |

|

Table 1.1.14

Detection Limit of the

Overall Procedure for Zinc |

|

|

| mass per sample (µg) |

intensity |

|

| 0 |

805.8 |

| 2.5 |

879.8 |

| 5 |

1088.1 |

| 10 |

1445.5 |

| 20 |

2201.2 |

| 30 |

3046.4 |

Figure 1.1.14. Plot of data to determine

DLOP/RQL for Zinc (Y= 76.0X + 725.7) |

| 40 |

3825.4 |

| 50 |

4482.3 |

|

1.2

Storage Test

Storage samples were prepared by

liquid-spiking Ghost Wipes at the target concentration.

Twelve storage samples were prepared. Three samples were

analyzed on the day prepared. Nine of the samples were

stored at ambient temperature (about 22ºC). At 5-day

intervals three samples were analyzed. Results were blank

corrected.

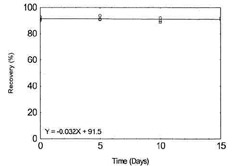

Table 1.2.1

Storage Test for

Beryllium |

|

|

| time (days) |

recovery (%) |

|

| 0 |

90.2 |

91.3 |

92.8 |

| 5 |

90.7 |

93.7 |

91.2 |

| 10 |

90.1 |

88.9 |

92.0 |

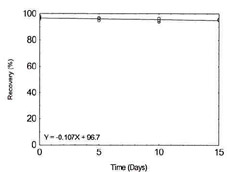

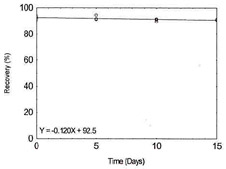

Figure 1.2.1. Storage test for

Beryllium. |

| 15 |

91.1 |

91.3 |

91.9 |

|

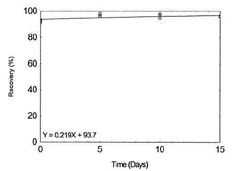

Table 1.2.2

Storage Test for Cadmium |

|

|

| time (days) |

recovery (%) |

|

| 0 |

91.0 |

92.6 |

93.3 |

| 5 |

95.8 |

97.9 |

96.8 |

| 10 |

96.8 |

94.7 |

97.7 |

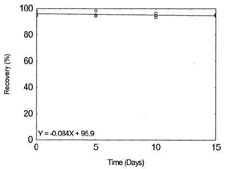

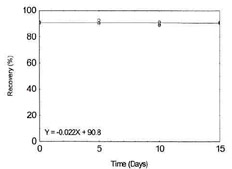

Figure 1.2.2. Storage test for

Cadmium. |

| 15 |

96.0 |

96.0 |

96.4 |

|

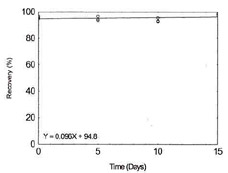

Table 1.2.3

Storage Test for Cobalt |

|

|

| time (days) |

recovery (%) |

|

| 0 |

94.8 |

95.9 |

96.7 |

| 5 |

93.6 |

96.6 |

94.3 |

| 10 |

93.2 |

92.7 |

95.6 |

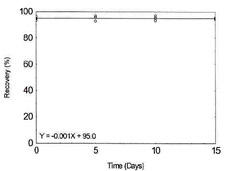

Figure 1.2.3. Storage test for

Cobalt. |

| 15 |

97.4 |

98.4 |

97.4 |

|

Table 1.2.4

Storage test for

Chromium |

|

|

| time (days) |

recovery (%) |

|

| 0 |

96.7 |

100.1 |

98.1 |

| 5 |

95.6 |

98.7 |

97.6 |

| 10 |

96.4 |

94.1 |

97.0 |

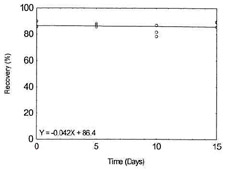

Figure 1.2.4. Storage test for

Chromium. |

| 15 |

96.7 |

98.5 |

97.0 |

|

Table 1.2.5

Storage Test for Copper |

|

|

| time (days) |

recovery (%) |

|

| 0 |

95.7 |

96.6 |

98.2 |

| 5 |

95.9 |

97.8 |

96.3 |

| 10 |

96.3 |

93.8 |

96.6 |

Figure 1.2.5. Storage test for

Copper. |

| 15 |

96.8 |

97.8 |

96.8 |

|

Table 1.2.6

Storage Test for Iron |

|

|

| time (days) |

recovery (%) |

|

| 0 |

97.5 |

98.6 |

100.3 |

| 5 |

97.1 |

99.0 |

97.7 |

| 10 |

97.7 |

95.9 |

98.8 |

Figure 1.2.6. Storage test for Iron. |

| 15 |

98.7 |

99.9 |

99.0 |

|

Table 1.2.7

Storage Test for

Manganese |

|

|

| time (days) |

recovery (%) |

|

| 0 |

95.2 |

98.5 |

96.8 |

| 5 |

94.6 |

97.5 |

96.5 |

| 10 |

96.0 |

93.8 |

96.6 |

Figure 1.2.7. Storage test for

Manganese. |

| 15 |

96.9 |

98.7 |

97.2 |

|

Table 1.2.8

Storage Test for

Molybdenum |

|

|

| time (days) |

recovery (%) |

|

| 0 |

96.0 |

97.0 |

98.0 |

| 5 |

96.3 |

97.0 |

95.0 |

| 10 |

94.7 |

93.6 |

96.5 |

Figure 1.2.8. Storage test for

Molybdenum. |

| 15 |

95.3 |

95.8 |

95.8 |

|

Table 1.2.9

Storage Test for Nickel |

|

|

| time (days) |

recovery (%) |

|

| 0 |

94.5 |

97.7 |

95.1 |

| 5 |

94.2 |

98.1 |

95.0 |

| 10 |

94.5 |

93.3 |

96.2 |

Figure 1.2.9. Storage test for

Nickel. |

| 15 |

94.4 |

94.6 |

95.3 |

|

Table 1.2.10

Storage Test for Lead |

|

|

| time (days) |

recovery (%) |

|

| 0 |

93.6 |

94.8 |

96.3 |

| 5 |

93.0 |

96.6 |

95.7 |

| 10 |

95.2 |

93.4 |

96.7 |

Figure 1.2.10. Storage test for

Lead. |

| 15 |

94.3 |

95.3 |

95.0 |

|

Table 1.2.11

Storage Test for

Antimony |

|

|

| time (days) |

recovery (%) |

|

| 0 |

85.8 |

85.5 |

90.1 |

| 5 |

86.9 |

88.2 |

85.6 |

| 10 |

78.2 |

81.7 |

86.6 |

Figure 1.2.11. Storage test for

Antimony. |

| 15 |

85.5 |

89.6 |

89.0 |

|

Table 1.2.12

Storage Test for

Vanadium |

|

|

| time (days) |

recovery (%) |

|

| 0 |

91.3 |

93.6 |

92.4 |

| 5 |

91.2 |

94.4 |

91.7 |

| 10 |

91.0 |

89.5 |

91.6 |

Figure 1.2.12. Storage test for

Vanadium. |

| 15 |

91.1 |

90.7 |

91.2 |

|

Table 1.2.13

Storage Test for Zinc |

|

|

| time (days) |

recovery (%) |

|

| 0 |

90.0 |

90.9 |

91.4 |

| 5 |

89.9 |

92.8 |

90.7 |

| 10 |

89.6 |

88.7 |

91.4 |

Figure 1.2.13. Storage test for

Zinc. |

| 15 |

90.3 |

91.4 |

90.9 |

|

1.3

Sampler Removal Efficiency

Six 100-cm2 glass plates

were liquid-spiked at the target concentrations and

allowed to dry. Samples were collected from each surface

by placing a Ghost Wipe folded in half at an outside edge

of the glass plate and progressing towards the center

making concentric squares of decreasing size while

applying firm pressure. The Ghost Wipe was folded in half

with the contaminant side in and the glass plate was wiped

a second time. The Ghost Wipe was again folded in half and

the surface wiped a third time. Results were blank

corrected.

Table 1.3.1

Sampler Removal Efficiency

Data for Beryllium on Ghost Wipes |

|

Table 1.3.2

Sampler Removal Efficiency

Data for Cadmium on Ghost Wipes |

|

|

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 4 |

3.770 |

94.2 |

|

10 |

9.300 |

93.0 |

| 4 |

3.755 |

93.9 |

|

10 |

9.168 |

91.6 |

| 4 |

3.938 |

98.4 |

|

10 |

9.625 |

96.2 |

| 4 |

3.880 |

97.0 |

|

10 |

9.535 |

95.4 |

| 4 |

3.848 |

96.0 |

|

10 |

9.595 |

96.0 |

| 4 |

3.785 |

84.4 |

|

10 |

8.330 |

83.3 |

|

|

|

Table 1.3.3

Sampler Removal Efficiency

Data for Cobalt on Ghost Wipes |

|

Table 1.3.4

Sampler Removal Efficiency

Data for Chromium on Ghost Wipes |

|

|

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 200 |

182.1 |

91.0 |

|

1000 |

964.5 |

96.4 |

| 200 |

182.0 |

91.0 |

|

1000 |

889.5 |

88.9 |

| 200 |

190.6 |

95.3 |

|

1000 |

1001.5 |

100.1 |

| 200 |

187.6 |

93.8 |

|

1000 |

917.5 |

91.7 |

| 200 |

187.8 |

93.9 |

|

1000 |

992.0 |

99.2 |

| 200 |

162.8 |

81.4 |

|

1000 |

927.0 |

92.7 |

|

|

|

Table 1.3.5

Sampler Removal Efficiency

Data for Copper on Ghost Wipes |

|

Table 1.3.6

Sampler Removal Efficiency

Data for Iron on Ghost Wipes |

|

|

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 200 |

194.1 |

97.0 |

|

2000 |

1914 |

95.7 |

| 200 |

193.6 |

96.8 |

|

2000 |

1913 |

95.6 |

| 200 |

200.7 |

100.4 |

|

2000 |

1987 |

99.4 |

| 200 |

195.6 |

97.9 |

|

2000 |

1940 |

97.0 |

| 200 |

197.3 |

98.6 |

|

2000 |

1957 |

97.8 |

| 200 |

172.5 |

86.2 |

|

2000 |

1704 |

85.2 |

|

|

|

Table 1.3.7

Sampler Removal Efficiency

Data for Manganese on Ghost Wipes |

|

Table 1.3.8

Sampler Removal Efficiency

Data for Molybdenum on Ghost Wipes |

|

|

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 400 |

385.1 |

96.3 |

|

1000 |

892.0 |

89.2 |

| 400 |

356.8 |

89.2 |

|

1000 |

698.5 |

69.8 |

| 400 |

400.0 |

100.0 |

|

1000 |

791.0 |

79.1 |

| 400 |

367.1 |

91.8 |

|

1000 |

780.5 |

78.0 |

| 400 |

395.7 |

98.9 |

|

1000 |

724.5 |

72.4 |

| 400 |

371.1 |

92.8 |

|

1000 |

749.0 |

74.9 |

|

|

|

Table 1.3.9

Sampler Removal Efficiency

Data for Nickel on Ghost Wipes |

|

Table 1.3.10

Sampler Removal Efficiency

Data for Lead on Ghost Wipes |

|

|

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 1000 |

913.5 |

91.4 |

|

100 |

90.95 |

91.0 |

| 1000 |

843.0 |

84.3 |

|

100 |

89.00 |

89.0 |

| 1000 |

955.0 |

95.5 |

|

100 |

93.60 |

93.6 |

| 1000 |

881.0 |

88.1 |

|

100 |

91.55 |

91.6 |

| 1000 |

941.5 |

94.2 |

|

100 |

92.75 |

92.8 |

| 1000 |

875.0 |

87.5 |

|

100 |

80.40 |

80.4 |

|

|

|

Table 1.3.11

Sampler Removal Efficiency

Data for Antimony on Ghost Wipes |

|

Table 1.3.12

Sampler Removal Efficiency

Data for Vanadium on Ghost Wipes |

|

|

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 1000 |

809.5 |

81.0 |

|

56 |

52.08 |

93.0 |

| 1000 |

654.5 |

65.4 |

|

56 |

49.41 |

88.2 |

| 1000 |

733.0 |

73.3 |

|

56 |

54.23 |

96.8 |

| 1000 |

717.5 |

71.8 |

|

56 |

50.23 |

89.7 |

| 1000 |

698.5 |

69.8 |

|

56 |

52.43 |

93.6 |

| 1000 |

690.5 |

69.0 |

|

56 |

50.98 |

91.0 |

|

|

|

Table 1.3.13

Sampler Removal Efficiency

Data for Zinc on Ghost Wipes |

|

| theoretical (µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

| 800 |

710.7 |

88.8 |

| 800 |

712.2 |

89.0 |

| 800 |

754.2 |

94.3 |

| 800 |

739.2 |

92.4 |

| 800 |

735.2 |

91.9 |

| 800 |

641.7 |

80.2 |

|

1.4 Analytical

Method Recovery and Stability of Digested Samples

1.4.1 Analytical Method

Recovery

Analytical method recovery (AMR) was

determined by liquid-spiking Ghost Wipes with the

analytes at the RQL, 0.1, 1.0, and 10 times the target

concentrations. These samples were stored overnight at

ambient temperature and then analyzed. Results were

blank corrected.

Table 1.4.1.1

Analytical Method

Recovery of Beryllium from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

0.017 |

114.7 |

82.4 |

94.1 |

82.4 |

93.4 |

| 0.1 |

0.4 |

95.6 |

99.5 |

96.1 |

97.4 |

97.2 |

| 1.0 |

4 |

94.5 |

95.1 |

90.6 |

94.4 |

93.6 |

| 10 |

40 |

92.2 |

92.9 |

93.6 |

94.4 |

93.3 |

| AMR |

|

|

|

|

|

94.4 |

|

Table 1.4.1.2

Analytical Method

Recovery of Cadmium from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

0.18 |

83.3 |

86.1 |

86.1 |

80.6 |

84.0 |

| 0.1 |

1 |

99.5 |

102.5 |

98.0 |

99.0 |

99.8 |

| 1.0 |

10 |

99.4 |

99.80 |

96.5 |

99.4 |

98.8 |

| 10 |

100 |

98.3 |

100.4 |

102.4 |

102.5 |

100.9 |

| AMR |

|

|

|

|

|

95.9 |

|

Table 1.4.1.3

Analytical Method

Recovery of Cobalt from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

1.1 |

105.9 |

92.7 |

94.1 |

97.7 |

97.6 |

| 0.1 |

20 |

99.2 |

101.9 |

100.2 |

101.1 |

100.6 |

| 1.0 |

200 |

98.2 |

98.1 |

93.7 |

97.7 |

96.9 |

| 10 |

2000 |

96.6 |

97.6 |

98.2 |

99.3 |

97.9 |

| AMR |

|

|

|

|

|

98.2 |

|

Table 1.4.1.4

Analytical Method

Recovery of Chromium from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

3.4 |

116.9 |

102.5 |

107.5 |

107.9 |

108.7 |

| 0.1 |

100 |

98.8 |

102.9 |

99.8 |

101.6 |

100.8 |

| 1.0 |

1000 |

99.3 |

98.9 |

95.3 |

99.1 |

98.2 |

| 10 |

10000 |

96.8 |

99.3 |

101.0 |

101.6 |

99.7 |

| AMR |

|

|

|

|

|

101.8 |

|

Table 1.4.1.5

Analytical Method

Recovery of Copper from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

1.5 |

110.0 |

111.7 |

100.0 |

89.7 |

102.8 |

| 0.1 |

20 |

99.8 |

102.7 |

101.4 |

101.0 |

101.2 |

| 1.0 |

200 |

98.0 |

97.4 |

97.4 |

97.4 |

96.6 |

| 10 |

2000 |

94.8 |

97.5 |

99.4 |

99.4 |

97.7 |

| AMR |

|

|

|

|

|

99.6 |

|

Table 1.4.1.6

Analytical Method

Recovery of Iron from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

5.1 |

131.9 |

112.9 |

107.4 |

93.0 |

111.3 |

| 0.1 |

200 |

102.3 |

106.2 |

102.9 |

104.2 |

103.9 |

| 1.0 |

2000 |

101.2 |

100.8 |

97.0 |

101.1 |

100.0 |

| 10 |

20000 |

98.5 |

101.7 |

103.8 |

103.8 |

102.0 |

| AMR |

|

|

|

|

|

104.3 |

|

Table 1.4.1.7

Analytical Method

Recovery of Manganese from Ghost Wipes |

|

| level |

sample number

|

| ×

target concn |

µg per

sampler |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

0.97 |

121.0 |

107.4 |

137.7 |

165.6 |

132.9 |

| 0.1 |

40 |

99.2 |

103.0 |

100.3 |

101.9 |

101.1 |

| 1.0 |

400 |

99.1 |

98.6 |

95.1 |

98.7 |

97.9 |

| 10 |

4000 |

96.4 |

99.0 |

100.7 |

101.2 |

99.3 |

| AMR |

|

|

|

|

|

107.8 |

|

Table 1.4.1.8

Analytical Method